The pick-up machine is a mechanical device that realizes the safe area of the product to be delivered to the product according to the ideal trajectory after the product is taken from the mold by the principle of the mechanical connecting rod.

Automatic extracter pick-up machine

Product introduction:

The pick-up machine is a mechanical device that realizes the safe area of the product to be delivered to the product according to the ideal trajectory after the product is taken from the mold by the principle of the mechanical connecting rod.

Technical characteristics:

1. Horizontal multi-link arm is adopted, and the floor-standing installation design is compact and occupying a small area.

2. It adopts Taiwanese Cycloidal Pin Motor and Reducer. The arm is multi-speed control with higher aerodynamic stability, high speed movement and no impact.

3. The time parameter and position setting can be set through the touch screen. It has operation and fault self-diagnosis function, which can monitor the movement position of the pick-up machine.

4. Use Japanese TOYO absolute encoder to digitize the arm position.

5. The horizontal direction is driven by a motor.

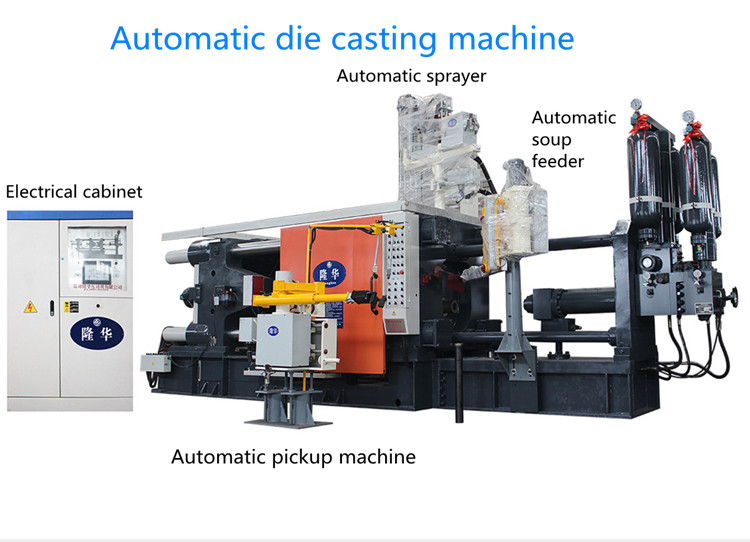

6. It can be single-action, or it can be connected with die-casting machine, soup machine and sprayer to become fully automated equipment.

Role of the pick-up machine:

1. It is to reduce manpower and program production.

2. Safe, stable and efficient.

3. The parts are taken gently to prevent collision, which is conducive to maintaining the appearance

of the workpiece and improving the quality.

4. More suitable for long-term, stable work.

Power: AC220V 50Hz 2KVA

Air source interface: 1 / 2 "5.0-6.0kg/cm

Main arm stroke: 650-950 mm

Cross trip: 40-180 mm

Action period: 4-8S

Main arm rotation: 90 degrees

Size: 1200 mm × 700 mm × 1000 mm

Machine weight: 350kg

|

Serial number |

operation |

Correlative factor |

Remarks |

|

1 |

Manual |

SB1 button selection manual |

The pick-up machine is in the manual state completely, the single action is realized when each action condition is satisfied |

|

2 |

Automatic |

SB1 button selection automatic |

The pick-up machine is completely in the automatic state, press the start button to realize the automatic operation. |

|

3 |

Arm advance |

Manual, the SB2 selection button turns counterclockwise to the left |

Die casting machine in the open die position, the main arm forward. Make sure there are no obstacles in front of the arm, otherwise the machine will be damaged. |

|

4 |

Arm recession |

Manual state, SB2 select button turn clockwise to the right |

The main arm moved backwards. |

|

5 |

Before Horizontal Action |

Manual state, SB3 horizontal button |

The main arm moves in the direction of the moving mode. |

|

6 |

After Horizontal Action |

Manual state, SB3 horizontal button |

The main arm moves towards the fixed mold. |

|

7 |

Hand clamp |

Manual state, SB4 clamp button |

Clamp hands to carry out clamping actions. |

|

8 |

Pinch hand |

Manual state, SB4 clamp button |

Hold hands in action. |

|

9 |

Arm rotation |

Manual status, SB5 arm rotation button |

The clamp moves 90 degrees clockwise. |

|

10 |

Arm rotation |

Manual status, SB5 arm rotation button |

The clamps turn 90 degrees counterclockwise. |

X

X