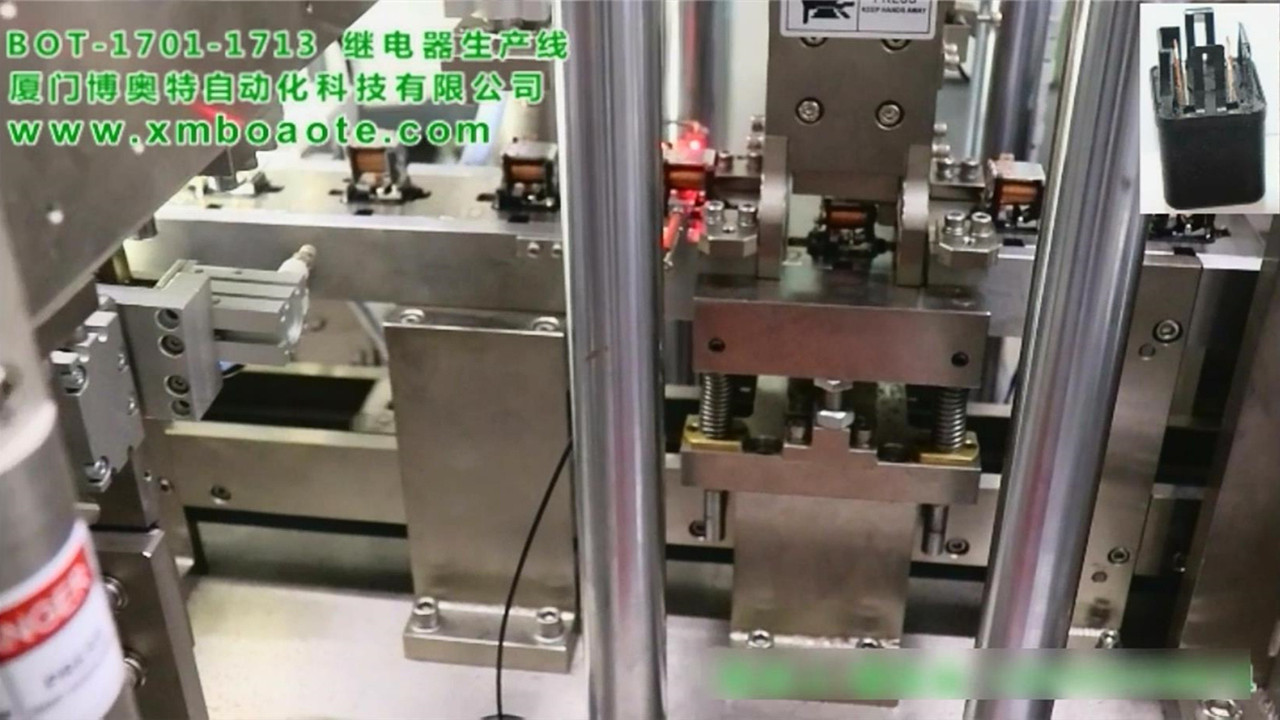

This production line successively completes the assembly of all parts of BGR249 relay including coil, iron core, yoke, moving spring, base plate, resistance, terminal A, terminal B, terminal C, terminal D, stop piece, shell and other parts, and carries out the inspection of all electrical parameters of the assembled products, selects the defective products found in the assembly and inspection process, and finally outputs the qualified finished products. This production line realizes the full automatic production of BGR249 relay, reduces the labor cost and improves the production efficiency.

This production line successively completes the assembly of all parts of BGR249 relay including coil, iron core, yoke, moving spring, base plate, resistance, terminal A, terminal B, terminal C, terminal D, stop piece, shell and other parts, and carries out the inspection of all electrical parameters of the assembled products, selects the defective products found in the assembly and inspection process, and finally outputs the qualified finished products. This production line realizes the full automatic production of BGR249 relay, reduces the labor cost and improves the production efficiency.

Automatic assembly machines:

1. Operation interface intuitive, easy to use, easy to maintain.

2. Production counter statistics, production can be intuitive and controllable.

3. Fault alarm display error, easy to troubleshoot.

4. The equipment is assembled in the form of rotary disc intermittent assembly structure, automatic feeding assembly;

|

No. |

Product |

Brand |

|

1 |

Air Cylinder |

SMC |

|

2 |

PLC |

Mitsubishi, OMRON, Panasonic, etc |

|

3 |

Sensor |

OMRON, Siemens, etc |

|

4 |

HML |

Mitsubishi, Kunluntongtai, DLLJSJ, etc |

|

5 |

Robot |

Epson |

|

6 |

Standard Part |

Mitsubishi |

|

Equipment technical parameters |

||||

|

productiveness |

Power |

Capacity |

Compressed air |

Overall dimensions( L*W*H ) |

|

1000-1200 PCS / H |

200/380 VAZ / 50HZ |

51KW |

0.50~0.80Mpa (0.50Mpa Best) |

43000 X 4800 X 1800 (mm) |

Xiamen Boaote Automation Technology Co., Ltd. was established in 2011. It's a development, design, manufacturing, sales, service, technical training and talent customization as one of the high-tech automation equipment professional manufacturers. Provide automatic assembly testing and packaging integration equipment for hardware products, DC contactors, relay products, new energy electronics, medical devices, auto parts, motors and other industries. Adhering to the concept of "quality for survival, integrity for development" and "leading technology to create first-class products ", the company provides high-quality automatic production equipment for continuous innovation and continuous improvement. Help customers improve production efficiency and reduce labor costs, cast first-class products, improve the comprehensive competitiveness of enterprises, and continue to focus on the electronics and electrical industry non-standard automation equipment and automation equipment R & D and manufacturing. Through 10 years of continuous development, the company's products stable and efficient application performance has been praised and trusted by many companies.

Hardware Lock; DC Contactor Products; Relay Products; Automotive New Energy and Motor Products; Bathroom and Hardware Products; Medical Equipment.

|

Packaging |

Wooden box, pallet, carton or as customer's request |

|

Carton size |

Usually it is customized. |

|

MOQ |

sample order is available. |

Q1: Are you a trading company or a manufacturer?

A: We are a high-tech manufacturer devoted ourselves to automation industry for 12+ years

Q2: Do you have an E-catalogue?

A: Yes. You can scan the QR code on the homepage of our official website and download the E-catalogue . Or leave your email. We will send it to you by email.

Q3: Do you have any successful customer example?

A: Sure. Firstly, we need to get your product samples and product drawings. After analyzing the products, we will give a quotation.

Q4: Could you please give me a quotation?

A: Sure. Firstly, we need to get your product samples and product drawings. After analyzing the products, we will give a quotation.

Q5: How long is your delivery time?

A: Normally in 65 days.

1、Warranty: 1 year from date of shipment. If any damage during the period caused by the seller, the seller shall then offer free maintenance on site and free component replacement (Exclusive of quick-wear parts).

2、The Seller offer life-long maintenance service, only labor cost will be needed if beyond the warranty period. If any damage parts needed component replacement and the Seller is not to blame, the Seller has the right to ask for material cost for replacement component.

3、The Seller will respond to any defects claims within 4 hours by telephone, email, and fax. For maintenance service in Fujian province within 36 hours, outside of Fujian province within 72 hours. For components replacement, the actual time can be negotiated additionally.

4、The Seller provide free training of operating personnel.

5、The Seller will also provide relevant technical information, including operating instructions & quick wear parts drawings.

6、The following situations are not included within the warranty period:

a. Quick wear parts confirmed by both sides;

b. Machine damage caused by natural disasters for example earthquake, fire, thunderstroke, and improper operation.

Can be designed and customized for customers, to a greater extent to meet the technical needs of different products.

Our company has obtained many patents and inventions.

X

X