It is with auto feeding system, suitable for cutting roll to roll fabric、embroidered textile、 cloth、felt、garment. Big working area. Auto feeder is optional.

4 head automatic feed laser cutting machine with auto feeding system, suitable for cutting roll to roll fabric、embroidered textile、 cloth、felt、garment. Big working area. Auto feeder is optional.

Advantage: of laser auto cloth cutting machine

1. High precision, High stability, Fast speed

2. Low consumption

3.Strong and durable frame, Long life

4.Imported guide rail and transmission belt

5.Imported reflector and focus lens

6.Stepping motor and driving system

7.Advanced copyrighted software

8.Excellent cooling system

9. LED realtime display

10.DSP intelligent main board

Applicable Industries: of roll fabric laser cutting machine

The machine is widely used in the industries such as shoe,bag, garment,toy,furniture, advertisement,car accessories,sports Accessories,etc.

Applicable Materials: of roll to roll laser cutter

Suitable for the materials, such as plush,fur,paper board,insole,PU,cloth,microfiber leather,

microfiber PU,etc.

Technical Parameters:of self feeding laser cutter

Laser Capacity | 100W 130W 150W CO2 glass tube |

Processing Area(mm) | 1600*1000 1800*1000 1800*1200 1800*1400 2000*1000 2000*1200mm |

Positional Accuracy | ±0.05mm |

Working way | Auto feeing |

Cutting Speed | 0-60m/min |

Max Traverse Speed | 0-64m/min |

Type of belt drive | X-direction outward sliding or inward sliding guide rail+3m synchronous belt; Y- direction outward sliding or inward sliding guide rail+3m synchronous belt |

Air exhaust | Big capacity lower air exhaust |

Graphic Format Supported | CDR,BMP,PLT,PCX,AI,DXF,DST,GIF, etc. |

Optical system | Φ25mm Molybdenum reflector; Φ25mm Silicon reflector; Φ20mm, focal length50.8 focusing mirror |

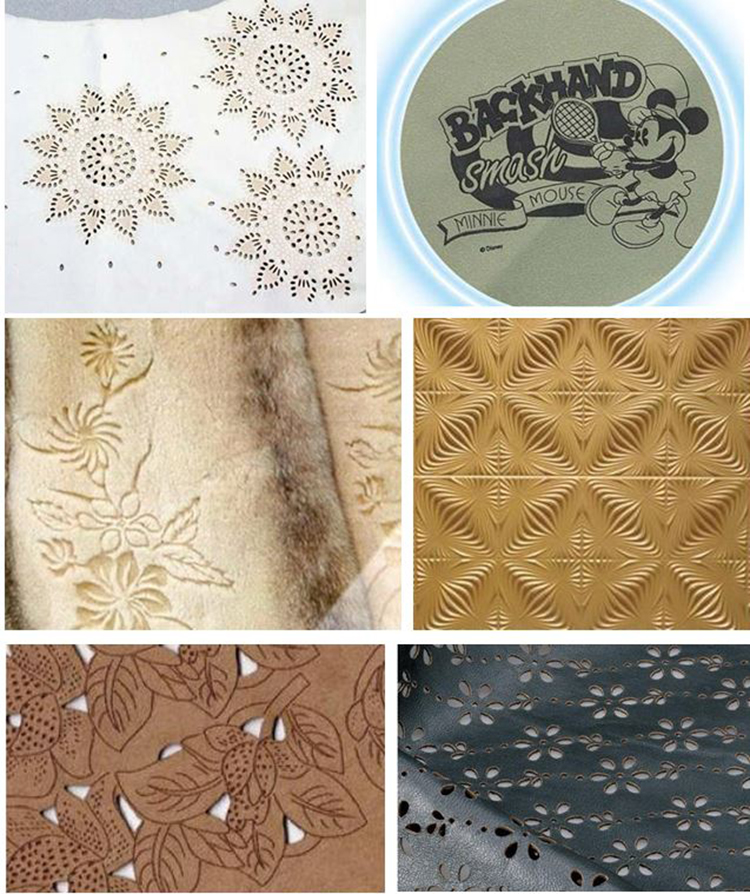

Sample show:

First part: Training: of fabric laser cutting machine

When the buyer finishes acceptance inspection in factory, the seller will train the buyer’s 2-3 workers and technicians free of charge (till the workers know how to operate the machine), the training will be the following:

1) Common sense of laser safety protection

2) Laser fundamental principle and the structure of laser engraving machine

3) The operating skill of laser engraving software

4) Machine’s operation and matters needing attention

5) Machine daily maintenance, the operation skill of laser adjustment and spare parts changing

6) The training time is about 3 days.

Second part: Installation and debugging:

The seller will install and debug the machine in the buyer’s factory under the buyer’s help when the machine arrives, the technician will carry the necessary special tools and debugging instruments.

Our Payment: of ccd camera laser cutting machine

1) Usually we accept T/T, Irrevocable L/C at sight.

2) 30% deposit, the 70% balance should be paid clear before delivery.

3) The delivery day is 7-10 working days.

4) The MOQ is 1set.

Our Service:

1) Guarantee for whole machine for 1 year.

2) Lifetime maintenance is free of charge.

3) We will provide the consumable parts at an agency price when you need replacement.

4) We offer English manual and CD for installing, operation and maintaining.

5) Our technician can be sent to your company to install the machine and train your workers if necessary.

Packaging & Shipping:

1) Standard seaworthy plywood case, without fumigation, can be exported directly.

2) Forklift-lift loading, much safer for machine.

3) We will arrange telex release for you or send original BL to you for customs clearance.

X

X