TAITIAN Hydraulic Press for Forming SMC Door Skin also called hydraulic compression molding press, it is applied in compression moulding of composites material such as SMC,BMC,FRP,GRP,GMT and so on. Our Hydraulic SMC Door Skin Forming Press and press lines offer the plastics industry superiour production capabilities, as well as repair and upgrade options. In addition to supplying new custom hydraulic SMC Door Skin forming press, TAITIAN provides a comprehensive list of repair and upgrade options for existing compression molding presses of all makes and models. Our compression molding presses are used to produce an extensive variety of innovative automotive, aerospace, industrial.

Main Specification:--Taitian offer customized press, all data include main force, working table, stroke,open height can be specified by customers.

|

Part No. |

TT-LM2000T |

||

|

Nominal Pressure |

Tons |

2000 |

|

|

Lifting Pressure |

Tons |

100 |

|

|

Max.Stroke of Slide |

mm |

1800 |

|

|

Max.Daylight |

mm |

2400 |

|

|

Working Table |

L-R |

mm |

4600 |

|

F-B |

mm |

3200 |

|

|

Slide Speed |

Fast Approach |

mm/s |

500 |

|

Pressing |

mm/s |

10-1 |

|

|

Fast Return |

mm/s |

350 |

|

|

Approx.Total Power |

KW |

210 |

|

|

Approx.Overal Dimension |

mm |

9660×4960×11410 |

|

Main Features of SMC Door forming press:

1. H Frame structure enjoys outstanding rigidity. It is mainly applied to compression moulding of SMC/FRP sheets. This serie of press has reached international advanced standards.

2. Adopt cartridge valve integrated system characterized by little impact, reliable movement, little leakage and long service life; Enjoy automatic lubrication system for guide rails. (Such technology is introduced from Taiwan.)

3. Mechanical-electrical-hydraulic integration safety device, for example, lower chamber support for the oil cylinder, interlock circuit of upper and lower chambers, all contributing to perfect safety. (We introduce advanced Taiwan hydraulic technology.)

4. Constant pressure and stroke can be set for same production. It is also functioned by adjustable pressure holding time delay.

5. Pressure and stroke setting is easy to be done within a certain range as per production requirements.

6. Adopt PLC+Touch Screen (HMI) integrated control. There are 3 operation manners, adjustable, manual and semi-automatic.

Applications

Hydraulic composites forming press is applied in compression moulding of composites material like SMC door skin,SMC motorboat and other BMC,FRP,GRP GMT composites materials.

Details Images

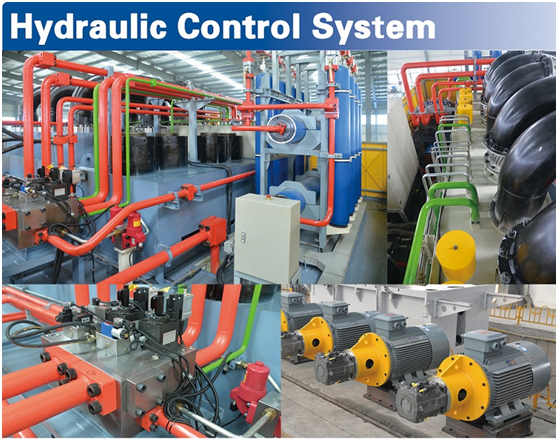

Hydraulic Control System

Hydraulic control system takes high precision logic valving system as standard. Pipeline configuration is simple and clear, making maintenance easy. Pipeline connection way preferentially adopts flange joint to avoid oil .

All motors, pumps and pipes are fitted based on advanced Taiwan technology to achieve shock-resistance.

Electric Control System

Electric box is featured with dustproof, waterproof and oil proof. Adopt Schneider electric units to ensure high quality. All units to ensure high quality. All units have labels, so it's clear to identify and easy to maintain.

Production Process:

Certification:

X

X