high-powered fiber laser cutter has 4000*2000mm big cutting area 3kw 6kw 8kw 10kw 12kw laser power option

Machinable materials: mild steel, stainless steel, aluminium, copper, brass, galvanized,materials thickness 0.5-50mm.

high power bslaser 12000w ipg CE stanard F4020HDE offers 4000*2000mm worksize ,basically meet big heavy sheet metal processing.

Main Features:

unattended laser processing.

Waste and workpiece collection drawer

Specifications:

|

Model |

F4020HDE (3015/6020 options) |

|

Working Area |

4000mm*2000mm |

|

Fiber Laser Power |

1000W/1500W/2000W/3000W/4000W/6000W/8000W/10000W/12000W |

|

X axis stroke |

2000mm |

|

Y axis stroke |

4000mm |

|

Z axis stroke |

120mm |

|

X/Y position accuracy |

±0.05mm/m |

|

X/Y Reposition Accuracy |

±0.03mm |

|

X/Y axis Max Acceleration |

1.5G |

|

Max Velocity of Movement |

120m/min |

|

Laser Cutting Head |

China WSX .Germany Precitec.Highyag. Swiss Raytools. |

|

Laser cnc control |

China Cypcut or PA.beckoff.ESA |

|

Servo Motor |

Japan or France Brand |

|

Rack and pinion |

Taiwan brand |

|

Workbench max load |

1200KG |

|

Min Cutting Kerf |

0.12mm |

|

Overall Dimension |

1150*3640mm*2100mm |

|

Machine Weight |

Approx 16000KG |

Figures1:better sheel plates .

around the whole machine key positions of operation ,made of brushed steel plate decoration. it is easy to clean wastes and dusts and not easy wear and tear.

industrial design.

Figure 2 : bslaser crossbeam .

Laser built with the Best Aviation Grade Extruding Aluminum Machine gantry.The crossbeam needs to be undergoing 8hrs cnc machining before powder coating and annealing.

with thick cross inner structure.

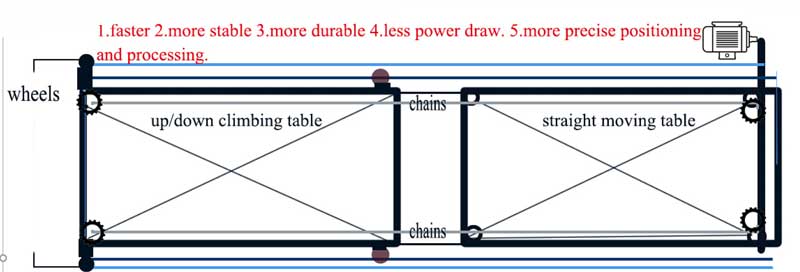

Figure 3: Shuttle Table structure demonstrate.

Good pallet changer helps improving half processing efficiency,exclusive type ,patent-owned.

Figure 4: Baisheng laser machine demonstrating its Shuttle Table workng on exhibtions.

For a span of 16 years time ,bslaser has been contributing on full series ,high and lower laser power laser machine design and production.

Figure 5:Testing high power laser cutting on baisheng's machine.

12kw cutting samples pieces

What are the fiber laser cutting machine advantages:

Fiber laseris a time saver and energy saver for metal fabrication and the main stream for now and the future .fiber lasers have become the true workhorse of metal fabrication,and they have never been more productive.

They cut nests at unprecedented speeds and produce finished parts with fine edge while power draw not so high .

Fiber laser cutting machine offers an unbeatable high production level and excellent cutting quality forthin and medium thickness sheets. The maximum sheet thickness depends on the chosen output power.

The high energy efficiency of the fiber laser ensures a significant reduction in energy consumption. The machines are available with output power ranging from 1000 watts to 12000 watts.

Laser Machine has Wide Application in Metal Fabrication

Laser cutting, laser welding, laser marking or laser drilling – lasers are used in a wide variety of processes in many different industrial sectors to optimize manufacturing processes and to ensure the high quality of components.

Why shuttle table is needed in Laser cutting machine?

Cutting is one of the 6 progresses of laser processing cycle,while shuttle table bring boost in productivity, suited for high-throughput environments.when one table is cutting ,the finished parts in other table can be picked up.

X

X