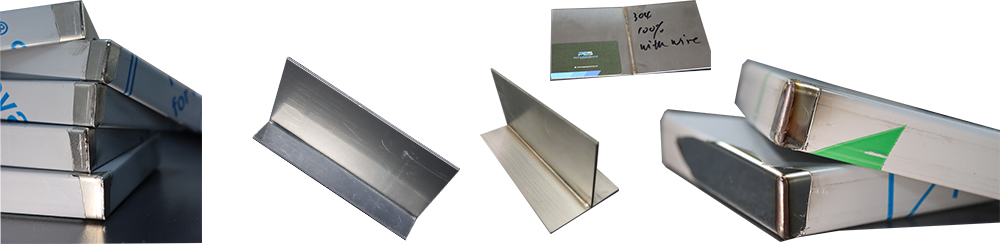

Along with the development of fiber laser source , hand-held laser welding machine was widely used and changed the industrial welding market by making it much simple for different angle and welding processing like tailored welding ,overlap welding ,T-profile welding ,Internal/external corner welding and wire feefer .it could completely replace the application of traditional arc welder and electric welder technology in thin stainless steel ,iron sheet, aluminum plate and other metal sheet.

Compare with Traditional Welding

Unskill worker can get started in 10 minutes,The welding speed is 4-10 times that of traditional welding, saving 3-5 professional welders. Concentrated energy, low thermal deformation, beautiful welding seam, deep penetration, high strength, can weld thin materials, can be welded by filler wire, or welded without wire.

High professional and technical requirements, high wages for workers, occupational diseases, large body injuries, slow welding speed, low efficiency, large heat influence and easy deformation, thick and irregular welds, requiring secondary polishing, large limitations, and can not weld too thin materials.

|

|

PES-W1000 Laser Welding Capacity

Thickness

Single side weld

Thickness

Double side weld

Thickness

Wire weld

Material

Sianless steel

3mm

6mm

2.5mm

Galvanized steel

3mm

6mm

2.5mm

Mild steel

3mm

6mm

2.5mm

Titanium alloy

3mm

6mm

2.5mm

Aluminum

2mm

4mm

1.8mm

Copper

1mm

2mm

0.8mm

X

X