100 Ton Glycol chiller for nano brewery

Great quality beer is dependent on a

variety of factors, the most critical of which is the flavor. The taste of beer

is affected greatly by its temperature at fermentation. Keeping the taste of

beer consistent keeps customers delighted and committed to your brand, and this

can be achieved by maintaining ideal process temperatures inside the brewer

during production.

The most effective way to maintain stable

process temperatures inside a brewing unit is to utilize brewery chillers,

which are typically glycol chillers. Click here to learn more about our

Standard Flow Air Cooled Portable Chillers for breweries.

Brewery glycol chillers are cooling units

that utilize propylene glycol (an organic anti-freeze agent) or a mix of

propylene glycol and water to extract excess heat from a brewing process and

dissipate it in a heat exchanger or refrigeration system. Brewery glycol

chillers provide the close temperature tolerance necessary to produce final

products of the highest quality.

Glycol chillers are suitable for specific

chilling applications within the brewery industry. Some typical examples

include:

Wort

Brite tanks

Fermenters

Two-stage heat exchangers

Some examples of the industry-specific

chillers we offer are:

Brewing Counterflow Chiller

Nano Brewery Chiller

Brew House Chiller

A glycol chiller for brewery systems

circulates supercooled glycol around a closed circuit. This closed loop is

comprised of tubing that connects to the input and output sections of the

chiller unit, and the heat exchanger. To cool wort, the glycol then circulates

through the heat exchanger, cooling the vessel.

Propylene glycol has a freezing point of

-74.2 °F (-59 °C) while a mixture of propylene glycol and water will maintain a

more moderate freezing point. Thus, a water/glycol brewery chilling system can

cool wort much faster than a water-only chiller without producing harmful ice

in the insides of the brewing vessel.

●:Temperature control -35℃ to 5℃

●:SS brazed Plate Heat Exchanger or 316 SS

shell and tube evaporator

●:Glycol mixture or salt marine suitable

●:Screw or piston compressor available

●:Safety protection covered low-temperature

chiller

●:Schneider electrical components

●:PLC / Touch screen/Mic-computer control

panel.

Nano Brewery chiller Product Display

Compressor features:

•New screw type compressor with 20%-30% higher in efficiency.

•Cooling capacity control available at four steps (100%-75%-50%-25%), three steps (100%-66%-33%) or no steps control system.

•High efficiency, low noise and vibration, easy to install.

•Environmental protection refrigerant R134a, R407c available.

Control operation system:

•SIEMENS PLC program control system, human-computer interface with big LED touch panel, running state displaying in multi-language, and self-diagnosis for easy operation and supervision.

•Extended industrial interface, convenient for being computer monitor via network.

Completely safety protection function:

•Multi-safety protection by high and low pressure, compressor overheating, overloading, over temperature, flow switch, phase sequence, phase-missing, exhaust overheating and anti-freezing.

Low Temperature Chiller Application

All low-temperature chillers manufactured by OUMAL, supplying constant glycol water is the ideal cooling partner for breweries, wineries, cider mills, and spirits, beverage, dairy milk, yogurt machine, laboratories, semiconductor, medical, pilot plants, and some other applications that require accurate and precise ultra-low temperature control.

Products Specification

| Item Model | OMC-100WSL | |||

| Norminal cooling capacity | Temp | -10℃ | 186.9 | |

| -20℃ | 127.9 | |||

| -30℃ | 79.9 | |||

| Input Power | KW | 88 | ||

| Power Supply | 3PH-380V/415V 50HZ(220V/440V 60HZ)) | |||

| Refrigerant | Type | R22 (R404A) | ||

| Control Mode | Expansion Valve | |||

| Compressor | Type | Semi-Hermetic Screw | ||

| Power | KW | 88 | ||

| Start-up Mode | Y-△ | |||

| Capacity Control | % | 0-25-50-75-100 (0-33-66-100) | ||

| Evaporator | Type | Temp | Shell and Tube | |

| Chilled Water Flow | -10℃ | m3/h | 32.1 | |

| -20℃ | 22.0 | |||

| -30℃ | 13.7 | |||

| Pipe Diameter | Inch | 4” | ||

| Condenser | Type | Shell and Tube | ||

| Cooling water flow | m3/h | 47.1 | ||

| Pipe Diameter | Inch | 4" | ||

| Dimension | Length | mm | 2750 | |

| Width | mm | 1050 | ||

| Height | mm | 1600 | ||

| Net Weight | kg | 1720 | ||

| Running Weight | kg | 1960 | ||

| Safety Protection: Compressor over temperature protection, over load protection, high and low pressure protection, anti-freezing protection, reversed and lacking phase protection, fusible blug, flow switch | ||||

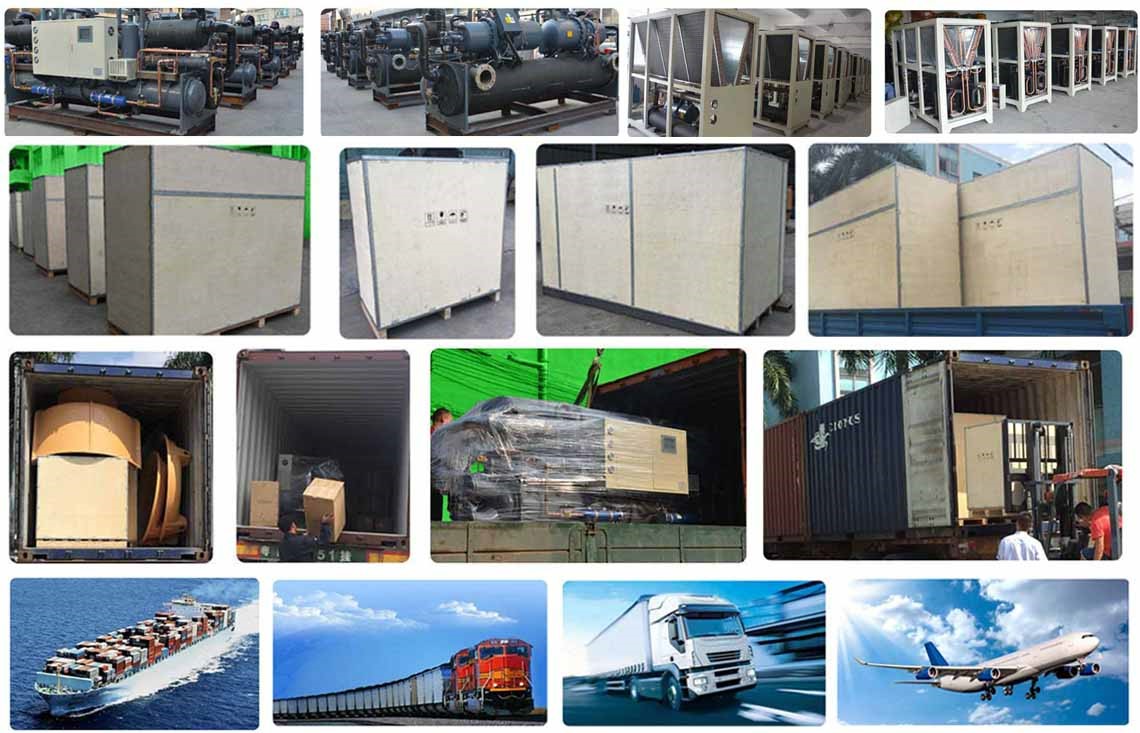

Package and Shipping

FAQ

Q1: Could you help us to recommend the model for our project?

A1: Yes, we have engineer to check the details and make the scheme for you. Based on the following:

1)Cooling capacity;

2)chilled water inlet and outlet temperature

3)chilled water flow

4) Refrigerant;

5) Ambient temperature;

6)Voltage;

7) Be used for what industry?

8)Any other special requirements?

Q2: How to ensure your product with good quality?

A2: All our products with CE certificate. And use the well-know brand accessories, such as copeland, danfoss,Hanbell, Bitzer compressor Emerson expansion Valve, Siemens controller.

also can be customized. All OUMAL Chillers are factory tested under load conditions to ensure good quality and easy installation for users

Q3: What's the warranty?

A3: 15 months warranty for free if confirmed by both side damage in the quality reason.

Q4: Whats your payment term?

A4: We accept T/T, LC, Western Union, etc. Normally, 30% deposit for production, 70% balance before shipment.

Q5: Are you a manufacturer?

A5: Yes, we have more than 15 years in water chiller business. Also have patent on the water chiller appearance.

The control box design make the unit safety and stably.

Q6: How can i Place an order

A6: Click Below to fill the table or Call 0086 15112554736

X

X