Die Casting machines are applicable to manufacture of automobile and motorcycle parts,electric escalator handrail/steps, industrial/road/railway/air/agricultural machinery, streetlights shells,pot light shells, building material parts, furniture, aluminum arts, copper arts, magnesium alloy products.

The product description

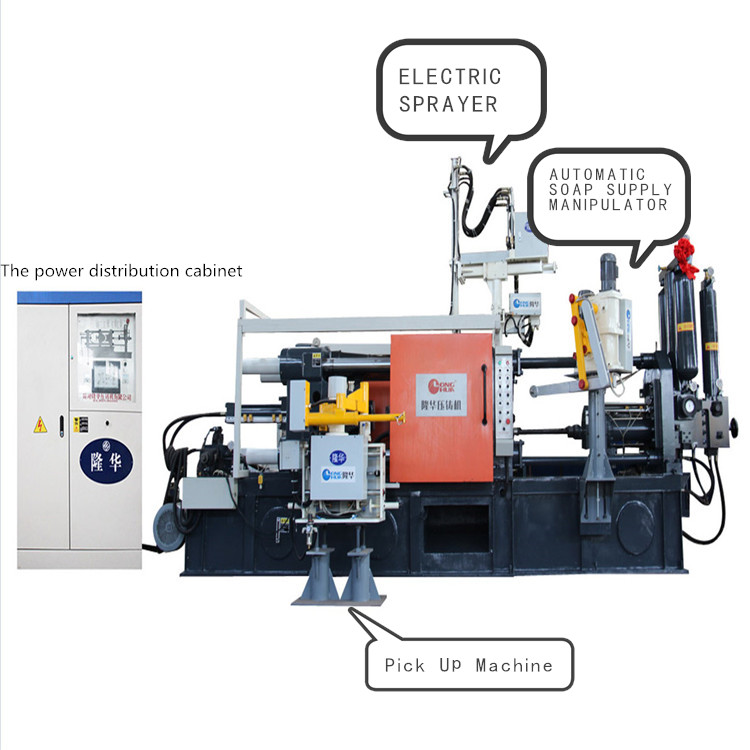

The die casting machine is superior in performance high in productivity and smooth in operation.

Small or large casting clusters

- Non-ferrous metals including zinc, aluminium, bronze and brass alloys

- Moulding chamber easily adaptable for shell-, sand- and block moulds

Product parameters

LH series of standard parameter table (300T)

|

ITEMS |

Unit |

Specification |

|

HYDRAULIC WORKING PRESSURE |

MPa |

14 |

|

CLAMPING FORCE |

KN |

3000 |

|

SPACE BETWEEN TIE BARS |

mm |

560*560 |

|

Tie Bar Diameter |

mm |

¢110 |

|

DIE OPENING STROKE |

mm |

420 |

|

INJECTION FORCE(intensify) |

KN |

240 |

|

Plunger launch distance |

mm |

140 |

|

Injection position |

mm |

0 -- 160 |

|

PLUNGER DIAMETER |

mm |

¢50----¢70 |

|

INJECTION STROKE |

mm |

420 |

|

Casting pressure (intensify) |

MPa |

143/99/73 |

|

Casting Fiange Protrusion |

mm |

12 |

|

Casting Fiange Diameter |

mm |

110 |

|

MAX CASTING AREA UNDER 40Mpa |

CM2

|

700 |

|

lnjection Weight(Al) |

Kg |

3.5 |

|

Die Height(Min--Max) |

mm |

250~650 |

|

EJECTOR FORCE |

KN |

150 |

|

EJECTOR STROKE |

mm |

120 |

|

Motor Capacity |

Kw |

15 |

|

Machine Dimensions (L*W*H) |

m |

6.4*1.7*2.8 |

|

Referential Machine Weight For Uplifting |

T |

12.5 |

|

Oil Tank Capacity |

L |

750 |

WE reserve the right to make any technical improvement without further notice

Worldwide distribution of our die casting machines

Our Service:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

X

X