NVSU333A UV-LED is widely used in high precision curing, ink curing (printing), bill checker etc. It's also the best way to solidify UV glue.

NVSU333A 365nm , high Power UV-LED Light Chips,long lifetime

Main parameter

● Pb-free Reflow Soldering Application

● Built-in ESD Protection Device

● RoHS Compliant

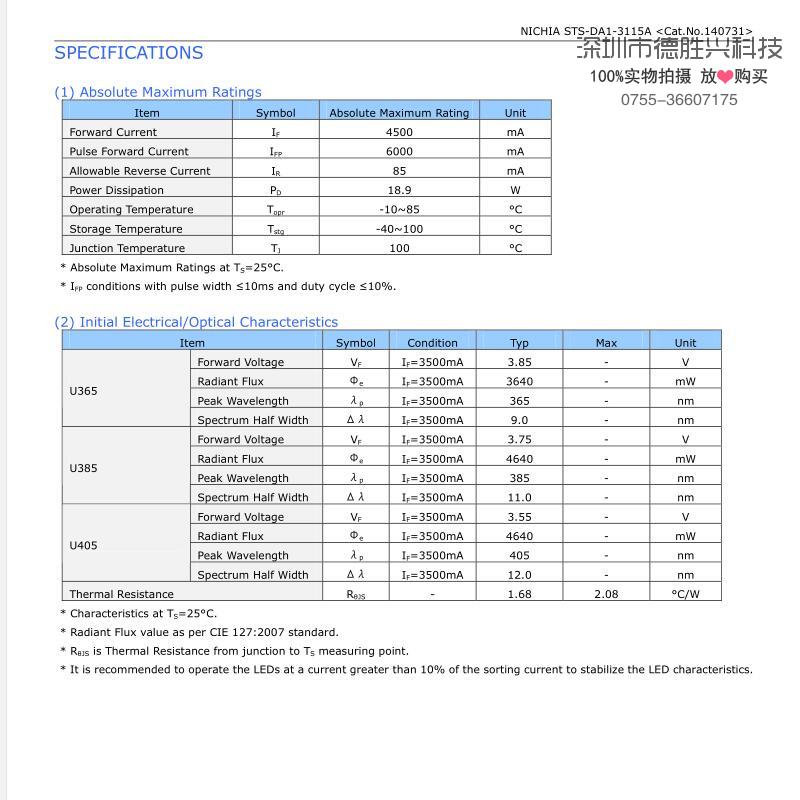

NVSU333ASPECIFICATIONS:

(1) Absolute Maximum Ratings

Forward Current I F 4500 mA

Pulse Forward Current I FP 6000 mA

Allowable Reverse Current I R 85 mA

Power Dissipation P D 18.9 W

Operating Temperature T opr -10~85 °C

Storage Temperature T stg -40~100 °C

Junction Temperature T J 100 °C

* Absolute Maximum Ratings at T S =25°C.

* I FP conditions with pulse width ≤10ms and duty cycle ≤10%.

(2) Initial Electrical/Optical Characteristics

(2) Initial Electrical/Optical Characteristics

Forward Voltage V F I F =3500mA 3.85V

Radiant Flux Φ e I F =3500mA 3640mW

Peak Wavelength λ p I F =3500mA 365nm

Spectrum Half Width Δλ I F =3500mA 9.0nm

* Characteristics at T S =25°C.

* Radiant Flux value as per CIE 127:2007 standard.

* R θJS is the thermal resistance from the junction to the T S measurement point.

* It is recommended to operate the LEDs at a current greater than 10% of the sorting current to stabilize the LED characteristics.

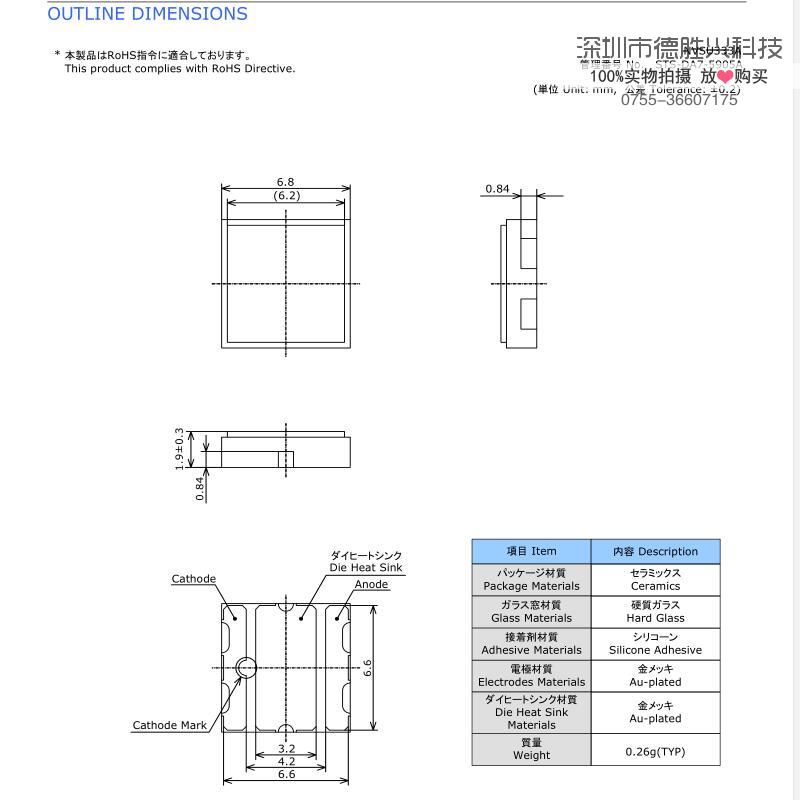

(3)Size

LxWxH(mm) 6.8x6.8x1.9

(4)NVSU333A Applications

Ink curing ,Lithography,Resin curing,Fluorescence Excitation,UV glue curing,Gap bonding,Magnetic-particle inspection etc.

X

X