|

Minimum Order Quantity: |

1 Set |

|

Price: |

|

|

Packaging Details: |

Wood case |

|

Delivery Time: |

In 7 Working Days |

|

Payment Terms: |

T/T, WESTERN UNION |

|

Supply Ability: |

500 Sets/Month |

Description:

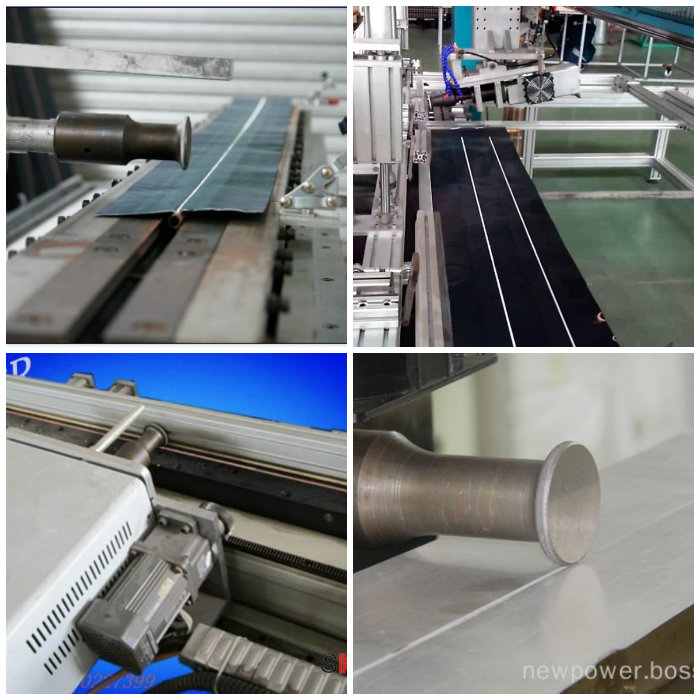

By using the ultrasonic high frequency vibration principle, the ultrasonic metal welder converts the ultrasonic vibration energy into friction energy to transfer the metal’s surface. Under condition of producing the heat by the friction and putting a pressure to the metal, the metal pieces will fuse.

Applications:

Hot Forging: Aims to fabricate the work pieces of certain temperature into other shapes through forging press with the help of punch press ,forging machine or other equipments.

Smelting:Mainly aims to melt the metal into liquid by using the high temperature, which is mainly applicable to smelting of iron, steel, copper, aluminum, zinc as well as various precious metals;

Heat Treatment:It is mainly aims to change the hardening of the materials through the heat treatment to work pieces. Such as, quench for various hardware and tolls, automobile and motorcycle, machine tools, hardware parts and machine parts, hardware mold, etc.

Welding/Brazing:It mainly aims to melt the solder by heating it to a certain temperature for the purpose of connecting two types of metals of the same material or different material

Annealing:Annealing of various stainless steel products and other work pieces , such as stainless steel basin, stainless steel tube, cue ,brass lock, aluminum radiator and so on .

Specifications: Model W-20M Frequency 20 KHz Output Power 2000 W Voltage 220 V Switch Handle or foot switch Power Adjusting Step or continuous Working Time Control 24 Hours Weight 20-30 KG ( Determined by the size of the horn ) Generator V6.0

Competitive Advantage:

Fast Heating: The minimum rate of heating is less than one second (rate of heating is available for adjustment and control)

Wide Coverage of Heating: It can be used to heat various metal parts (replace removable induction coil as per different shape).

Easy Installation: It can be used once it is connected with power source, induction coil as well as water supply pipe and rising pipe; it is small in size and light in weight.

Easy Operation: You can learn to operate it within several minutes.

Fast start-up: It can be started to perform heating operation on condition that water and power supply is available.

Low Power Consumption: As compared with conventional vacuum tube high frequency equipments, it can save the power by approximately 70%. The smaller the size of the work pieces, the lower power consumption would be.

High Effectiveness: It has such features as uniform heating ( it is applicable to adjust the spacing of the induction coil to ensure the appropriate temperature as required by each part of work piece ), fast warming and limited oxic horizon, and can guard against any waste after annealing.

Comprehensive Protection: It has such functions as overvoltage, over-current, overheat and water shortage alarm indications as well as automatic control and protection.

Controllable Temperature: It is applicable to control the temperature for heating work pieces as per the preset heating time, and thereby control the heating temperature at a certain technical point.

Comprehensive Full Load Design: It can work continuously for 24 hours

Small Size and Light Weight: It has a weight of only several dozens of kilograms, of which, the limited floor space can effectively save the workshop space. Sound operational environment: it is favorable for environmental protection, conservation of energy and safety operation, which is free of any noise, exhaust gas and dust.

Elimination of High Voltage: it requires no step-up transformer which may produce approximately ten thousand voltages, and thus can ensure the maximum safety.

X

X