Grain dryers is widely used in drying grain material such as grain, rice, corn, wheat, soybean, sorghum, etc .It used to dry them in order to make it safe for storage.Rice dryer is used to dry paddy in order to make it safe for storage .

Multiple choice fuel type: coal, wood, diesel, gas LPG or NG, biomass such as rice husk, presses straw bricks,corn cob, coconut shell, wood chip.

Many grains can be dried on the same equipment to meet the drying needs of different grains. It can dry feed grain, commercial grain, and seed grain to improve the utilization rate and reduce the drying time of the equipment,so normally we called it corn dryer,wheat dryer,maize dryer,rice dryers,rice drying etc. The grain drying is very suitable for grain processing plants, farms, grain stations, grain farmers, cooperatives, grain depots, grain, and oil processing plants, and other user groups.

The drying of rice is different from that of other grains. Rice is a heat-sensitive crop. Too fast drying speed or improper parameter selection can easily lead to burst waist. The so-called burst waist refers to the microscopic cracks on the surface of the grains after drying or cooling, which will directly affect the broken rice rate when the rice is milled, thereby affecting the rice yield rate of the rice, and also directly affecting its output and economic value.

The grain dryers is suitable for rice, wheat, mung bean, sorghum, soybean, and other grains. This grain dryer uses hot air as the drying medium and adopts a circulating drying design to save energy. Moreover, it is equipped with an automatic temperature and moisture detection controller to avoid over-baking and ensure the quality of grains.

Advantage

1.Using large screw feeder, large plastic steel ladle, stainless steel mesh plate, long-term use

2. Forced dispersion device and multiple rotary valves are used for quantitative feeding and circulation so that the seeds and grains can be dried evenly

3.High-efficiency exhaust fan, fully open drying layer, fast drying speed, and high efficiency. The heat source can choose fuel oil, and can also choose the equipped combustion furnace.

4. The professional dryer specially developed and designed for high-quality small packaging can create the highest profit for you .

Best drying quality

Low temperature drying ,quality assurance ,reduce grain broken rate (<0.5%) and grain crack rate (<3%) ,without loss weight, ensure efficient germination rate.

Higher durability

Tempering layer and discharge layer was made by stainless steel material.

Easy operation and repair

Automatic control, control panel with button .Easily repaired by users.

Low drying cost

Use rice husk ,firewood, corn cobs, anthracite coal and other biomass energy as fuel which can reduce the drying cost.

Perfect service

The professional technicians give you the best service in a short-time.

Application Range

Our products are applied to drying rice, corn, wheat, peanut, soybean, mung bean, coffee bean,sunflower seed and their seeds.

Standard Devices

Online Moisture Monitor ;Conveying System ;Unloading System ; Drying System ;Elevator; Automatic Control System; Grain Temperature Sensor ;Fault Alarm ;Full Load Buzzer ;Hot Air Temperature Sensor ;Overload Protection Device; Leakage Protection Device;

Advanced drying technique features

●Large drying area ,drying to each paddy with high efficiency and average.

●Burner indirectly supply heat to grain, grain continuous circulation and friction each other during drying ,the tips on the grain is removed out to machine by centrifugal fan, get more clean after drying.

●Low temperature circulating drying, effectively reduce the breakage of grain ,and improve the quality of grain.

●Automatic display the working condition of dryer, easy operation.

●Online moisture meter, automatic test moisture ,auto-off after reach the setting moisture.

●Drying process average and easy clean, no mixing other seeds.

●The bearing is designed as low rotating speed, made in Japan, three-layer of protection device which keep away dust from outside during running.

●Big centrifugal fan, maximum air volume reach to 12000-14000m3/h,full pressure reach to 1000pa,effectively improving the drying speed with lower noise.

●The auger vanes uses 45 manganese steel ,hardness reach to HRC50 after treatment.

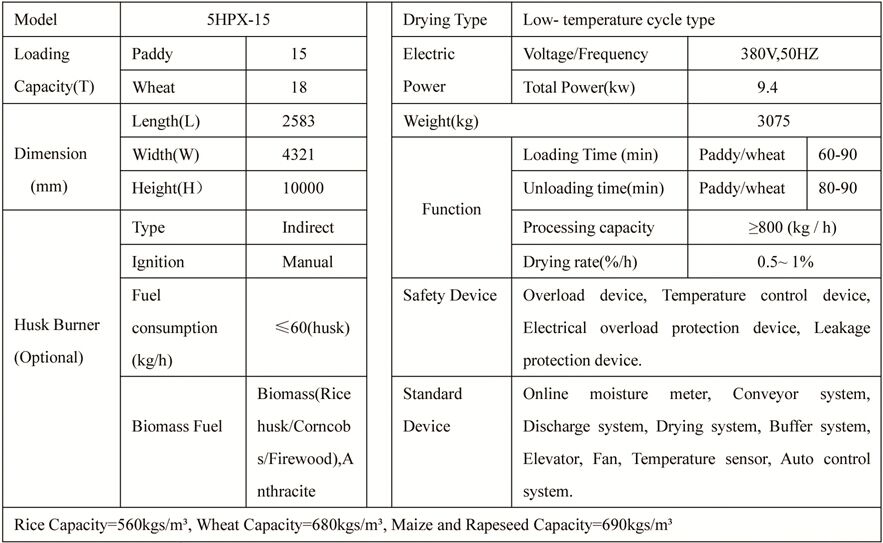

Parameter Table

The above table is for reference only, actual drying rate will vary by ambient temperature, relative humidity, grain variety, hot air temperature, moisture rate before and after drying.

Installation Details

1.Our company will arrange our engineer by custormer's request to install and debug until the grain dryer can get good drying effect;

2.We will supply basic drawing,installing drawing,and the flowing technical drawing.According to the installation instructions of manufacturer,the customer can install machine by yourself,It also can save cost;

3.If the customer don't need factory installed,we can negotiate to use third party installation;

4.We will assist the buyer to do the commodity inspection and other export affairs;

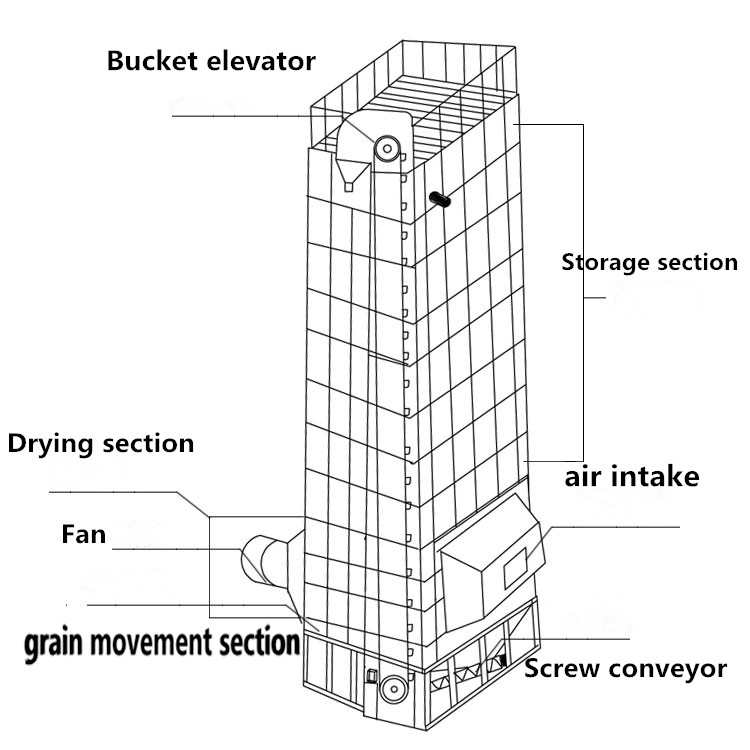

Structure characteristics

It is mainly composed of feeding device, bucket elevator, drying tower, hot blast stove, blower, moisture content detector, screw conveyor, electrical control box and other safety systems.

Among them, the hot blast stove can be used separately drying chili, cowpea, honeysuckle, vegetables and other sticks or block materials.

Performance characteristics

1. Reduction rate of moisture is slow, so that the end products can be seeds. The germination rate of the grain after drying won’t reduce.

2. More environmental protection. Close shells make it more environmental.

3. Auto feeding materials, discharging materials.

We have many installation cases and working videos.Please contact us freely if you need.

X

X