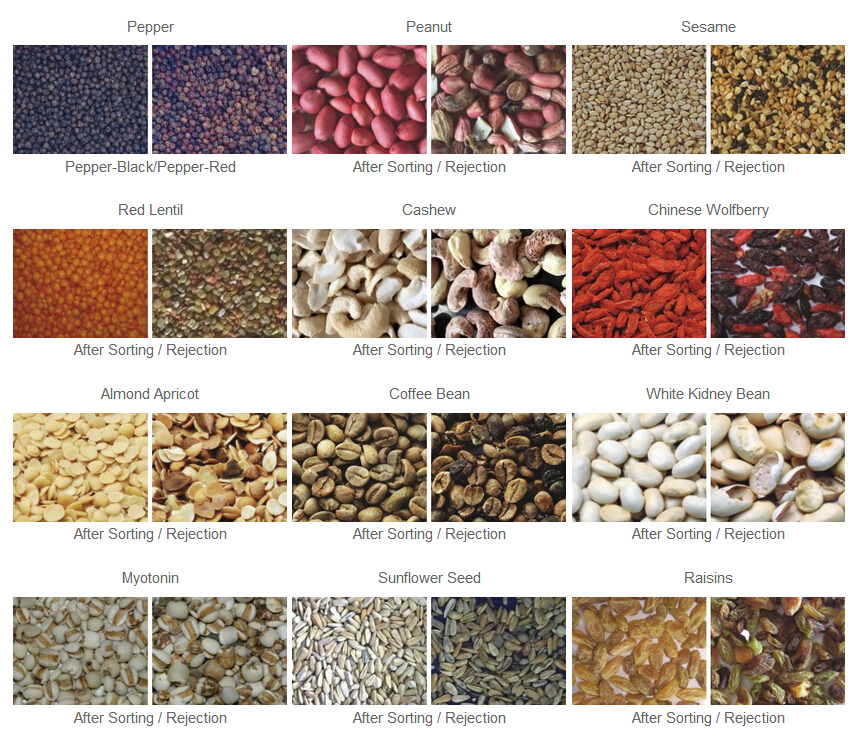

Grain sorting machine can sort grain,seeds,beans like pumpkin seeds,coffee beans,seeds,maize,wheat ,rice etc.Grain sorting is a crucial step in the agricultural industry to ensure the quality of the final product. Poor quality grains can reduce the overall value of the harvest and even cause health risks. However, traditional manual sorting methods are inefficient and time-consuming. Grain Sorting Machine

Improving Grain Quality with Color Sorting Machines

Introduction: Grain sorting is a crucial step in the agricultural industry to ensure the quality of the final product. Poor quality grains can reduce the overall value of the harvest and even cause health risks. However, traditional manual sorting methods are inefficient and time-consuming. That's where grain color sorting machines come in. These machines utilize advanced imaging technology to sort grains based on their color, shape, and texture. In this article, we'll explore how grain color sorting machines work and the advantages they offer for grain processing.

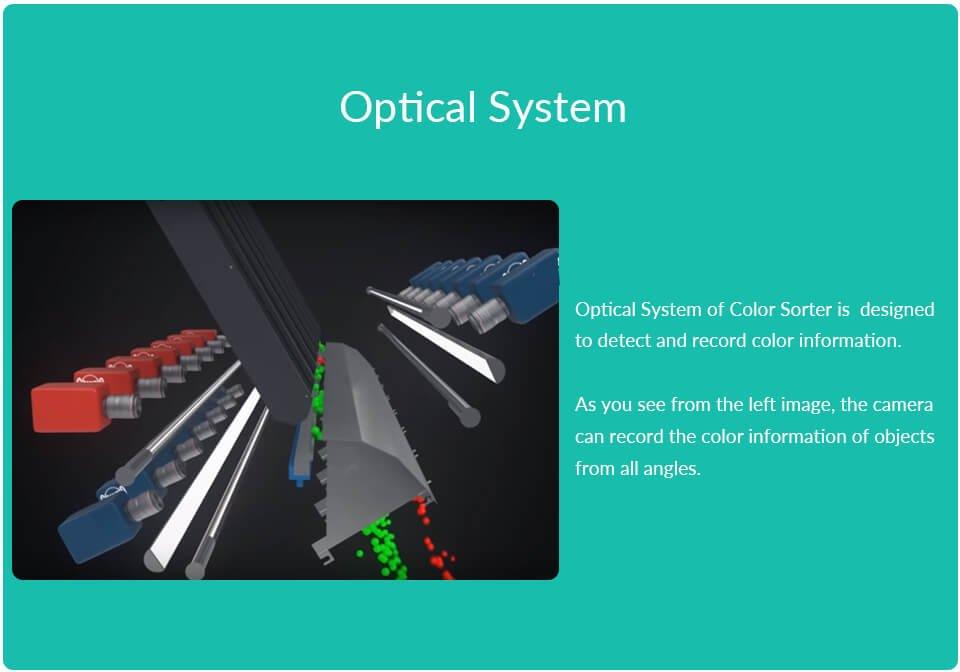

How Grain Color Sorting Machines Work: Grain color sorting machines use high-speed cameras and advanced software algorithms to capture images of each individual grain as it passes through the sorting process. The software analyzes the images and identifies any defects or impurities, such as broken kernels, discolored grains, and foreign material.

Once identified, the machine separates the defective grains from the good ones using a series of air jets or mechanical arms. This results in a batch of high-quality, uniformly colored grains that are ready for further processing or packaging.

Advantages:

1.Improved Quality: Grain color sorting machines can identify and remove defective or impure grains, resulting in a higher quality batch of grains that are more desirable to buyers.

2.Increased Efficiency: Sorting grains by hand can be a time-consuming and labor-intensive process

Products Features

1) The min. identify can be up to 0.04 mm2 ,

makes color sorting reach a new high level, meets demand of accurate sorting.

2) Advanced and Reasonable optics design guarantees accurate sorting.

3) Double sorting process guarantees final ideal sorting result.

4) Reasonable channel assigns suitable for sorting grain with various size.

5) Advanced production equipments from Germany and strict management under ISO9001:2008 guarantees machines' precision.

6) Great Data transferring Bandwidth guarantees the data transferred rapidly, makes machine perform consistently and stably.

7) Latest Patented technology of image processing algorithm upgrades the accuracy, and accelerates the operation speed.

8) Several sorting modes meet various requirements.

9) Advanced system design with China Patent guarantees machine run stably for a long time.

10) Concise touch panel from Japan helps customer operate easily.

Parameter Table

| Model | Z1-64 | Z2-128 | Z2-192 | Z4-256 | Z5-320 | Z6-384 | Z7-448 | Z10-640 | Z12-768 |

| Type | 6SZM-64 | 6SZM-128 | 6SZM-192 | 6SZM-256 | 6SZM-320 | 6SZM-384 | 6SZM-448 | 6SZM-640 | 6SZM-768 |

| Output(t/h) | 0.5-1 | 1.5-4 | 3-6 | 5-10 | 6-10 | 7-12 | 8-15 | 13-24 | 18-30 |

| Sorting Accuarcy(%) | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 | ≥99.99 |

| Optimized Carryover (Bad:Good) | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 | ≥20:1 |

| Weight (kg) | 400 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1400 | 1600 |

| Resolution(mm2) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

| Power(kw) | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 4.5 | 6.0 | 8.0 |

| Dimensions (LxWxH)(mm) | 1070*1650 x2010 |

1370x1650 x2010 |

1684x1650 x2010 |

1998x1650 x2010 |

2312x1650 x2010 |

2626x1650 x2010 |

2930x1650 x2010 |

4100x1650 x2010 |

2670x3000 x2010 |

| Power Supply(V/Hz) | 220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

220/50 (110/60) |

1. The above data is based on the 2% contamination, and real output depends on the material and its contamination.

2. If products update, no further notice. Please refer to the real machine.

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 10- 20 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

More information about color sorter

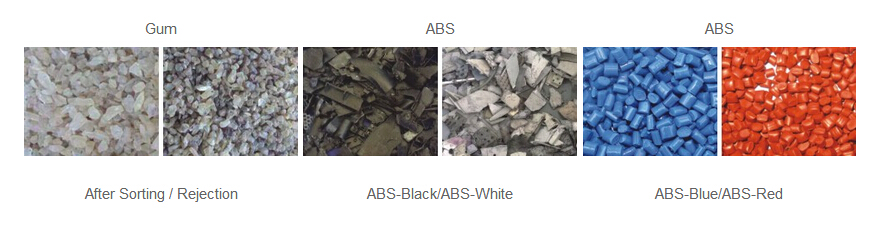

Separate Materials By Color

Color sorters are intensively effective in sorting materials of different colors. Rice, grains, millets, and cereals are examples you might need to sort based on colors.

Separate Materials By Sizes

It is prevalent to sort foods by size. In general, a color sorter can sort products by sizes of 0.1mm to 100mm.

Separate Materials By Shapes

Sorting by shape is very useful to classify food like tea leaves and seafood. You can set the parameters you want and let the machine do the work.

Separate Materials By Types

In some cases, you might need to sort materials like nuts, seeds, and beans by type. To classify them efficiently and pick only the healthy ones.

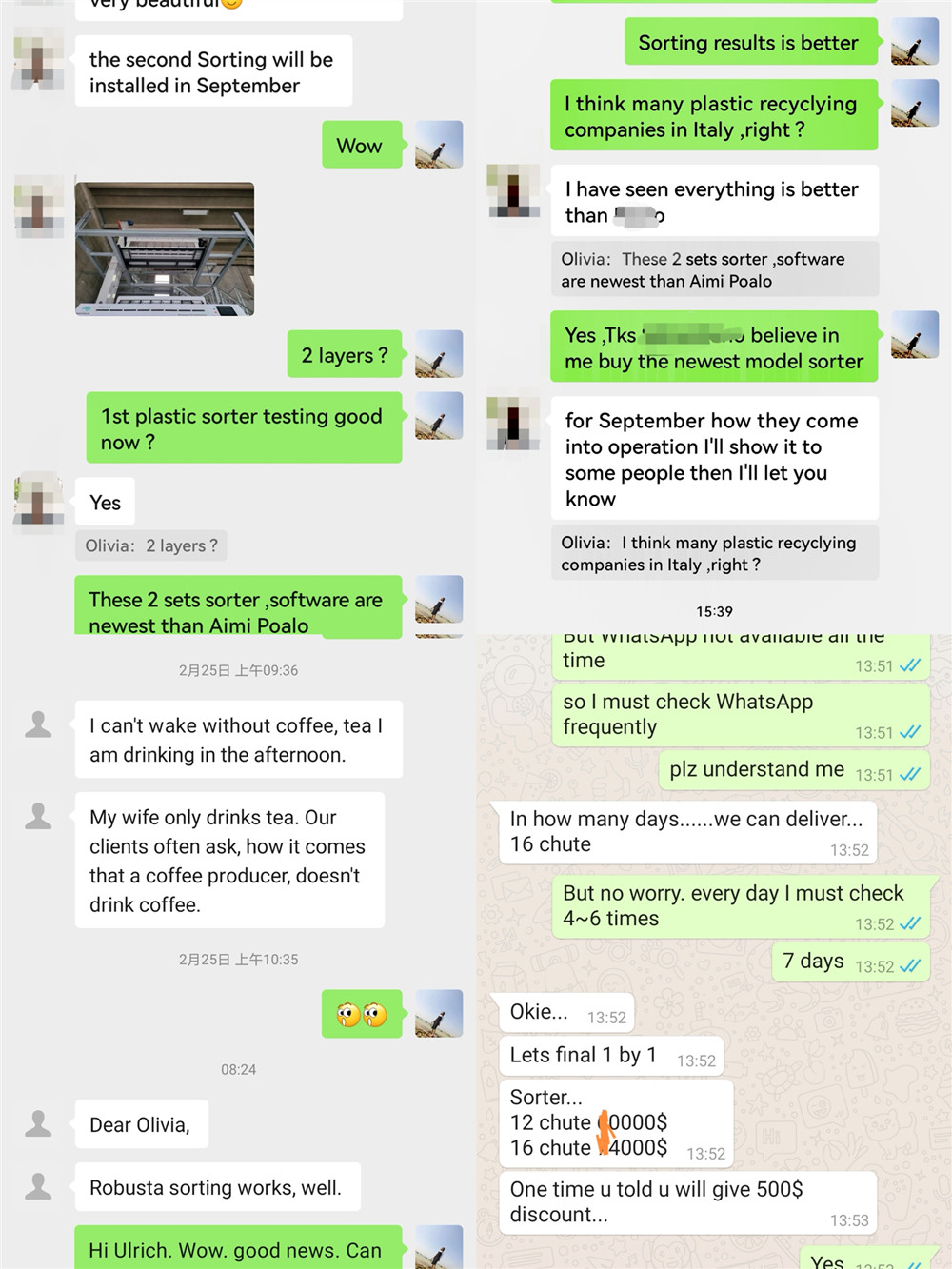

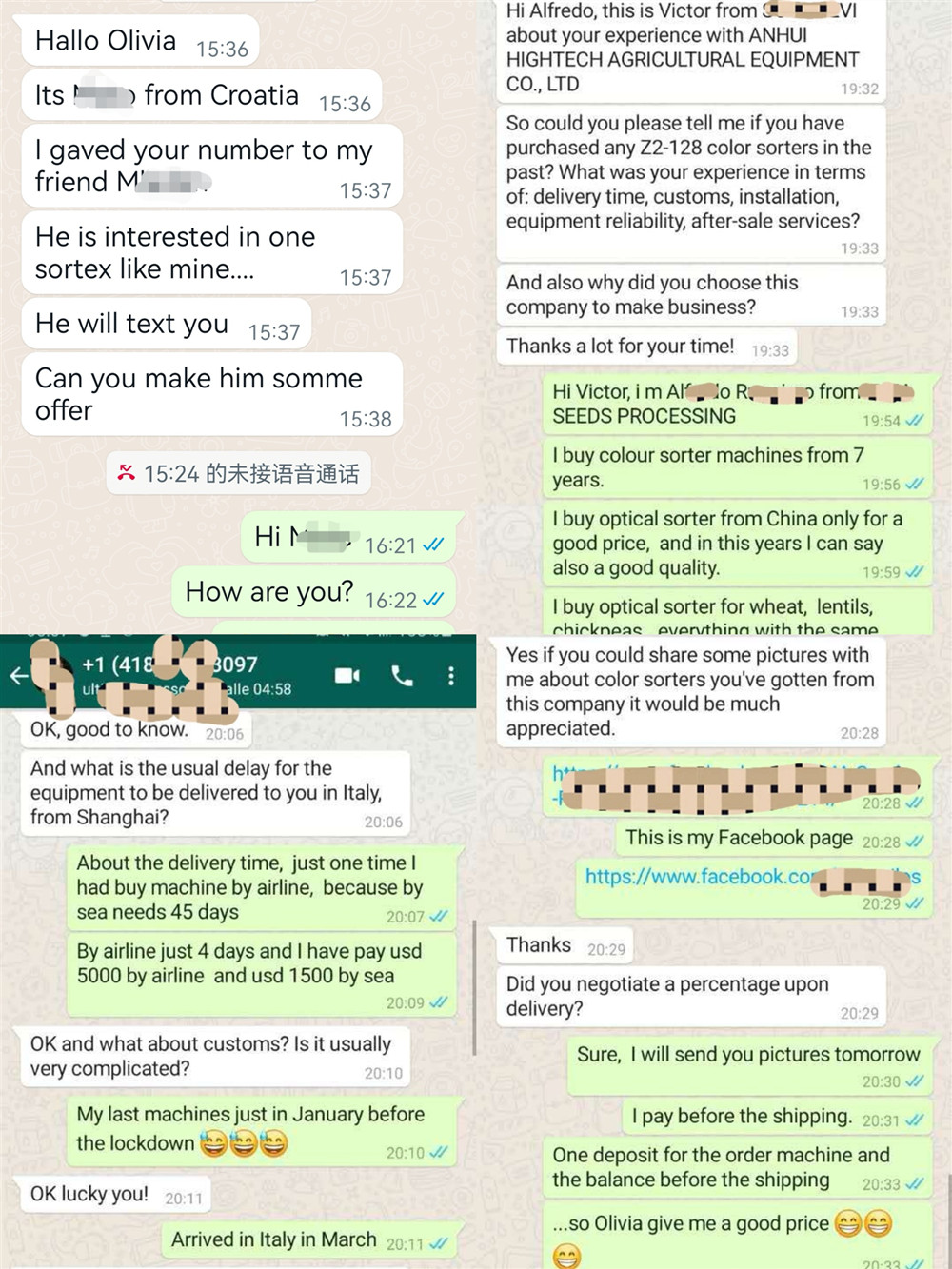

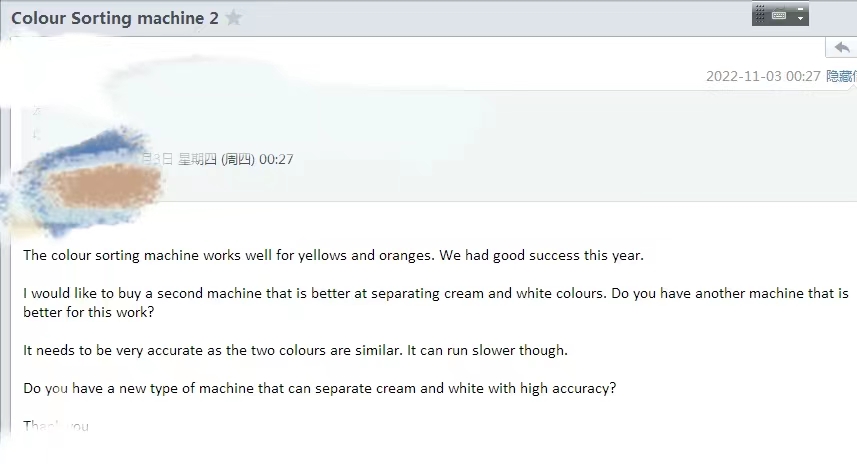

Customer Feedback Is The Driving Force Behind Our Progress:

Plywood Case Is Suitable For Sea/Road/Air Transport:

1. How to use the machine?

We will supply the Installation instructions and videos for guiding you how to set color sorter.

2. How long about the guarantee period?

Two years. And we supply lifelong software upgrade services for our customers.

3. Can you supply the air compressor, air tank and air filters?

Yes, we can provide above equipments, our standard offer includes color sorter machine with air compressor & air tank & air dryer & air filters.

4. Is oversea service available?

Yes, we will send engineer go abroad when you need it.

5.How to calculate Installation personnel cost?

On condition that customer requires to install, our company would like to send 1 engineer to guide for installation, then customer should to pay the cost, including transaction of engineer’s visa, transportation(air) for go abroad. and accommodation , local transportation and security when the engineer arrived.

6. If you have agent in our country?

We have agent in UK,New Zealand,Italy,Crotia,India, Guatemala,Finland,Malaysia,Bangladesh,Pakistan,Nigeria,Ukraine,Nicaragua etc. and we can provide after-sales service in your Country.

We have many installation cases and working videos.Please contact us freely if you need.

X

X