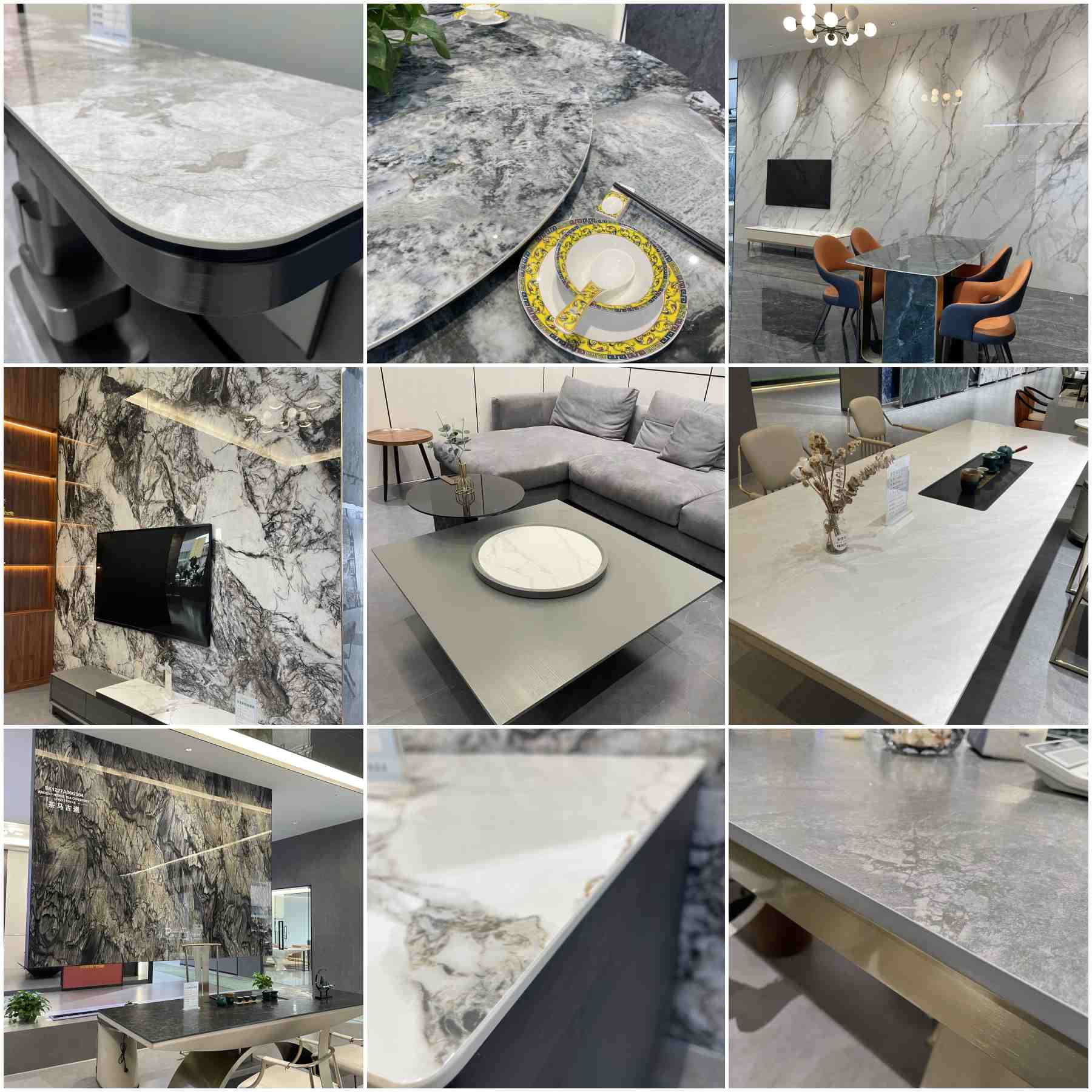

Exquisite high quality Ornate Scratch-resistant white sintered stone is one of our best seller. Exquisite and elegant, the white marble vein panel captures the timeless beauty and veining patterns of luxurious natural marble. Compared with marble, it is more easier to maintain and clean.

Product Description

|

Product name |

Exquisite high quality Ornate Scratch-resistant white sintered stone |

Brand name |

Aoli artificial stone |

|

Raw materialn |

natural minerals, ceramic powders, pigments, glass and porcelain powders, inorganic binders | ||

|

Available tile size |

305*305, 457*457, 600*600, 500*500 mm or other customized size |

||

|

Available slab size |

3200*1600mm/ 2700*800mm or other sizes |

||

|

Application |

wall cladding panel, floor paving tile, column, countertop, sink, window sill, molding or other special design interior decoration |

||

|

Thickness |

8, 12, 15 mm or other customized tile size |

||

|

MOQ |

100 square meters |

||

|

Quality Control |

Thickness tolerance: +/-1mm; Polished degree: more than 90; color difference control |

||

|

Edge finishes |

not finish, surface pattern, suggeting mitred edge |

||

|

Packing details |

Packed by strong plywood crates directly with thin foam inside, putting polished sides face-to-face; 15-18pcs/bundle, packed by strong seaworthy wooden bundle |

||

|

Production time |

15 - 20 days after deposit |

||

|

Production Ability |

200,000 ~ 300,000 square meters per month |

||

|

Payment terms |

30 % deposit to start production and rest pay for full sets of documents |

||

|

Sample availability |

Sample is ready and free, but express fee will be on your own |

||

Features and Benefits of sintered stone

1. Durability: Sintered stone is extremely resilient and long-lasting. It is made by compacting natural minerals and pigments under high pressure and high temperatures, resulting in a material that is resistant to scratches, stains, heat, and impact.

2. Strength: Sintered stone has impressive mechanical strength, making it suitable for a wide range of applications. It can withstand heavy loads and is less likely to chip or crack compared to other materials like natural stone or quartz.

3. Versatility: Sintered stone comes in various colors, patterns, and finishes. It can be manufactured to mimic the appearance of natural stone, concrete, wood, and other materials, offering a wide range of design options.

4. Non-porous: Sintered stone has a low water absorption rate, making it resistant to stains and easy to clean. Its non-porous surface also prevents the growth of bacteria and mold, making it a hygienic choice for kitchen countertops and bathroom surfaces.

5. UV resistance: Sintered stone is resistant to fading and discoloration caused by exposure to sunlight and UV rays. This property makes it suitable for both indoor and outdoor applications without compromising its appearance over time.

6. Sustainability: Sintered stone is an eco-friendly choice as it is predominantly composed of natural minerals and does not contain harmful substances. Additionally, the production processes used in manufacturing sintered stone aim to minimize waste and reduce environmental impact.

7. Maintenance: Sintered stone requires minimal maintenance. Its non-porous surface makes it easy to clean with simple household cleaning products, and it does not require regular sealing or polishing.

Projects application examples

Popular color palette

Package loading details

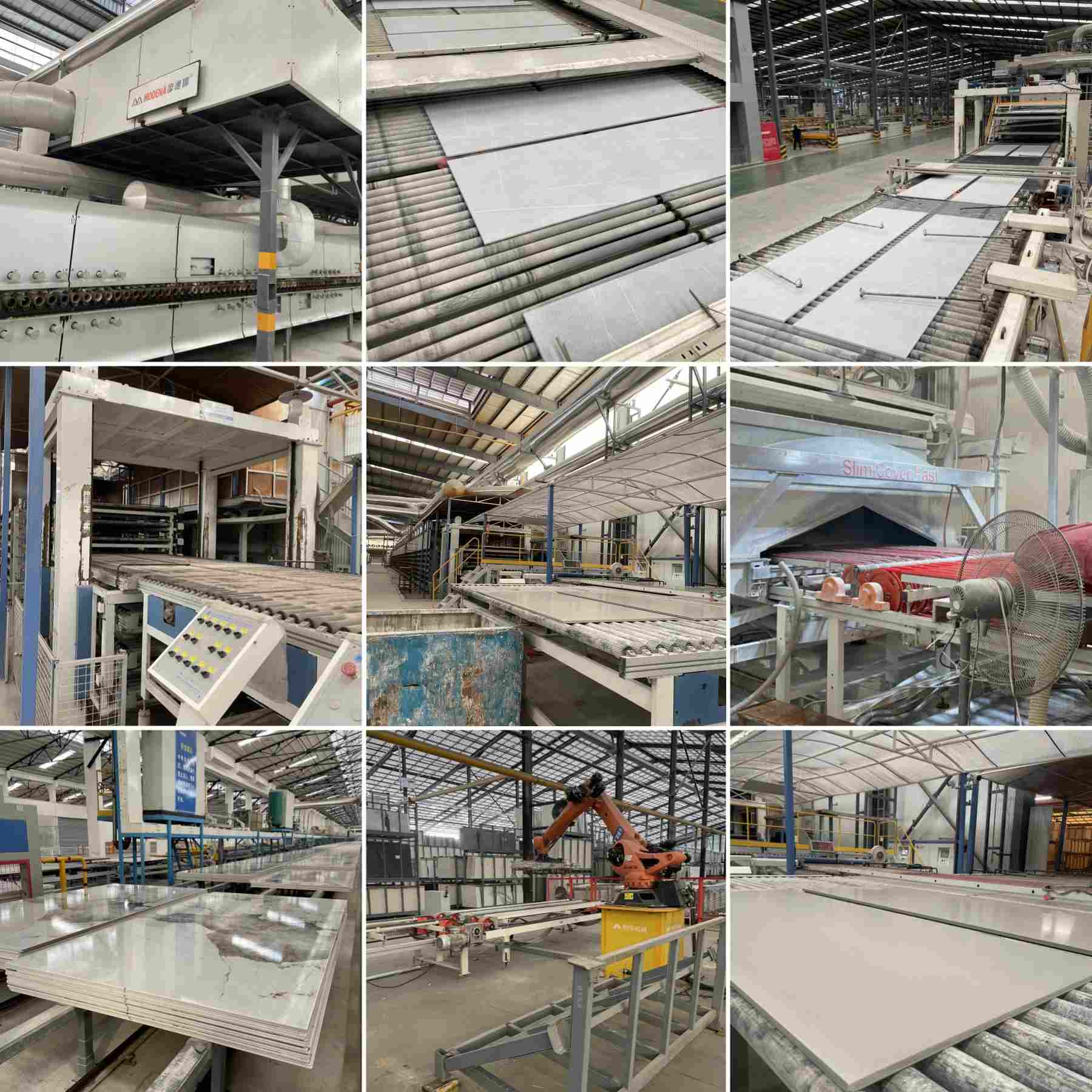

Factory viewing & Production machine

Why choose us

Nan an Aoli stone is a qualified and well-equipped artificial stone factory

More than 100,000 meters workshop

300 more skillful workers,

2 Auto artificial marble production lines,

9 sets imported diamond see-saw,

4 sets of Auto polishing machines,

10 infrared machines

several profile machine...

Our team at Xiamen international stone fair- supply better artificial marble

For more information of sintered stone colors, please visit our website

URL: http://www.aoli.biz/ http://www.aolistone.com/

How to start work with us?

Inquiry with detailed information ( color, chosen pattern, requested size, thickness, quantity ) →→ Counteroffer and confirming price by both sides →→ Checking sample →→

Sending 30% deposit to settle the order after checking performa invoice →→ Production

→→ Inspection →→ Paying rest for full set of documents to release the container →→ Quality and service feedback →→ Order completion

X

X