This litchi noodle machine can automatically identify the thickness of the plate, the processing process is safe, the processing effect is uniform, the plate is not easy to break, and it saves labor.

Product Introduction

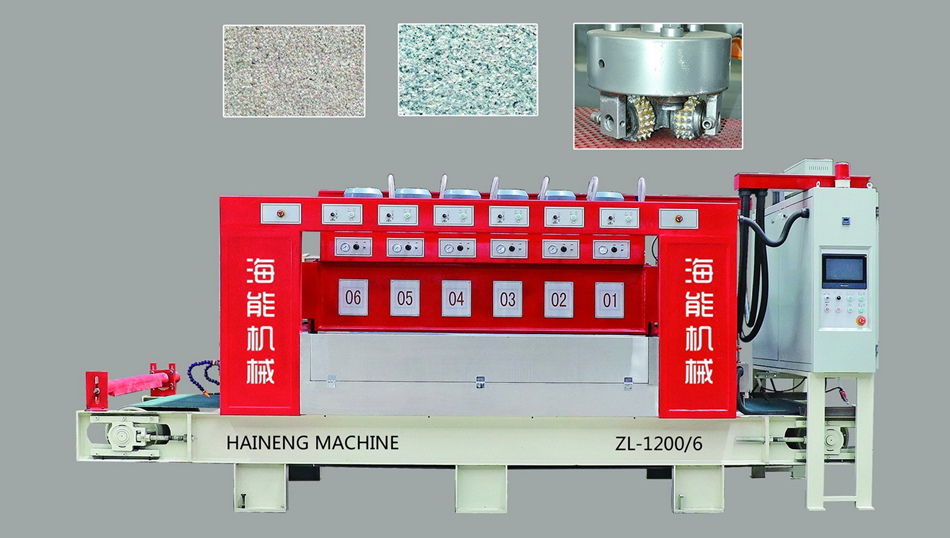

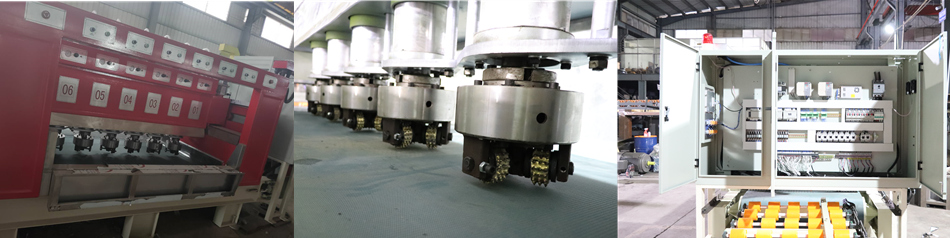

Full-automatic continuous litchi noodle mill, based on the principle of continuous walking, through the improvement of grinding head and program conversion, becomes a new type of continuous litchi noodle machine. The operation control system adopts PLC terminal control, and the parameter setting is carried out through the LCD touch screen. Grinding and polishing adopts pneumatic control, and its pressure is adjustable within the set value. This litchi noodle machine can automatically identify the thickness of the plate, the processing process is safe, the processing effect is uniform, the plate is not easy to break, and it saves labor.

|

Automatic Litchi Noodle Machine |

|||

|

Type |

Unit |

ZL-1200/6 |

ZL-1200/8 |

|

Point number |

pcs |

6 |

8 |

|

Main motor power |

kw |

5.5 |

5.5 |

|

Total power |

kw |

36 |

47 |

|

Mill diameter |

mm |

200 |

200 |

|

Grinding plate width |

mm |

1200 |

1200 |

|

Grinding plate thickness |

mm |

10-100 |

10-100 |

|

Beam swing speed |

m/min |

3-35 |

3-35 |

|

Into the plate velocity |

m/min |

1-4 |

1-4 |

|

Cooling water pressure |

mpa |

0.1-0.5 |

0.1-0.5 |

|

Water consumption |

m³/h |

6 |

8 |

|

Gas supply pressure |

mpa |

0.8 |

0.8 |

|

Overall dimensions |

mm |

4500×2700×2300 |

5200×2700×2300 |

|

Machine weight |

kg |

4000 |

5500 |

X

X