L-900 Automatic SMT splicing Machine

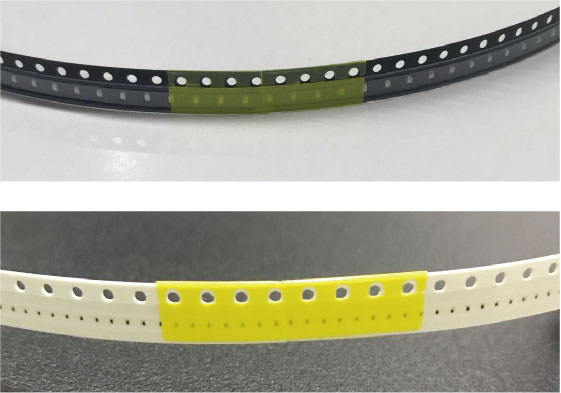

L-900 Automatic Splicing Machine is designed for the automatic produc[1]tion line of SMT placement machine. For paper tape and plastic tape with same specification, it can realize automatic correction and splicing of two rolls of tapes with a width of 8mm to 24mm. In the process of splicing, the equip[1]ment can automatically realize accurate cutting and splicing, and automatically connect the head and tail of two rolls of tapes by high adhesion film, so as to realize continuous production.

● Automatic splicing for 8\12\16\24mm width carrier tapes (01005 capable)

● Carrier tape thickness 0.25–1.4mm (paper) and 0.25-7.5mm (embossed) applicable

● Continuous operation for up to 16 hours once fully charged

● Up to 98% FPY

● Bluetooth and Wi-Fi connectivity to the factory MES

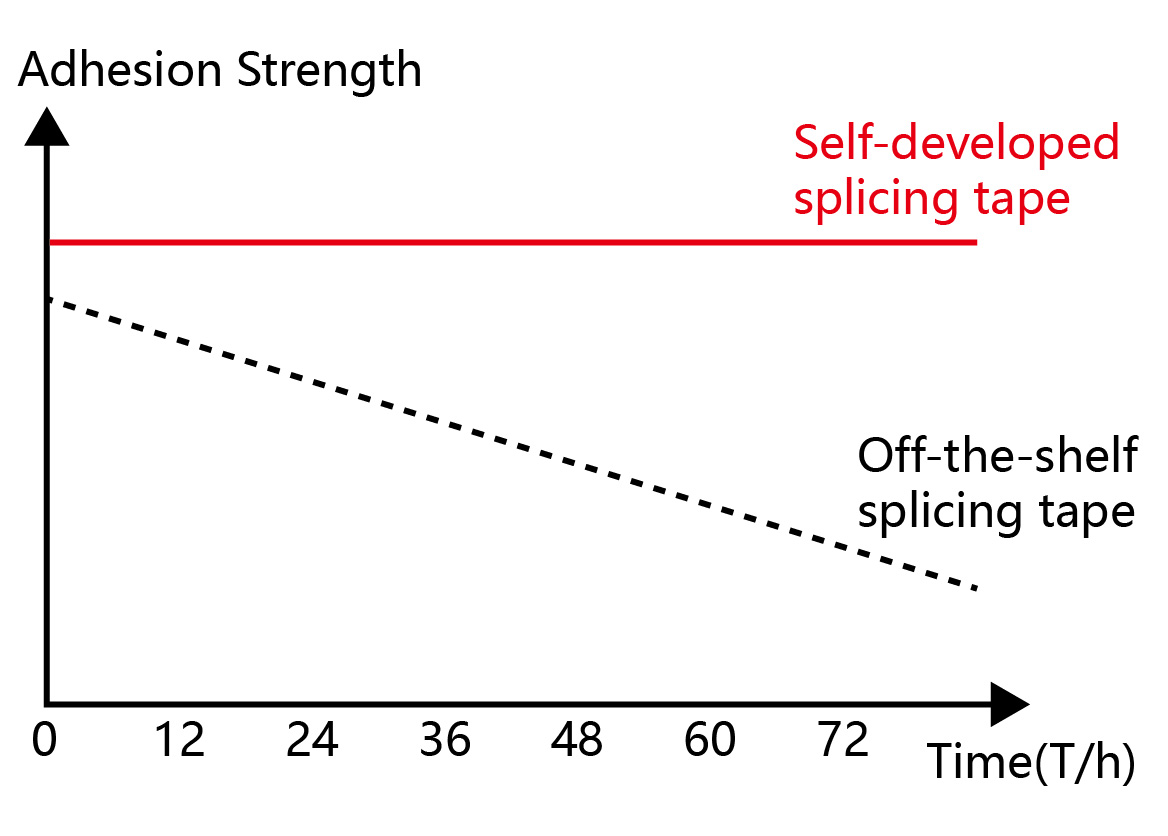

● Superior adhesive strength in comparison with traditional splice tape connector, thus enhancing splicing reliability

● Validation function available in both stand-alone and online mode

● Power-assisted (motor powered) wheels to facilitate movement on the shop floor

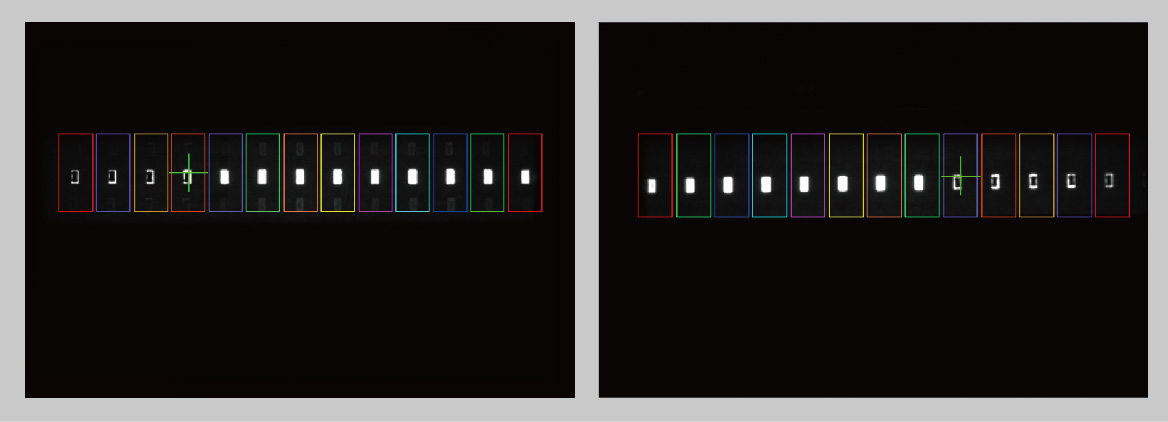

● Empty-pocket detection using vision inspection

TECHNICAL SPECIFICATIONS

|

Facilities Requirements |

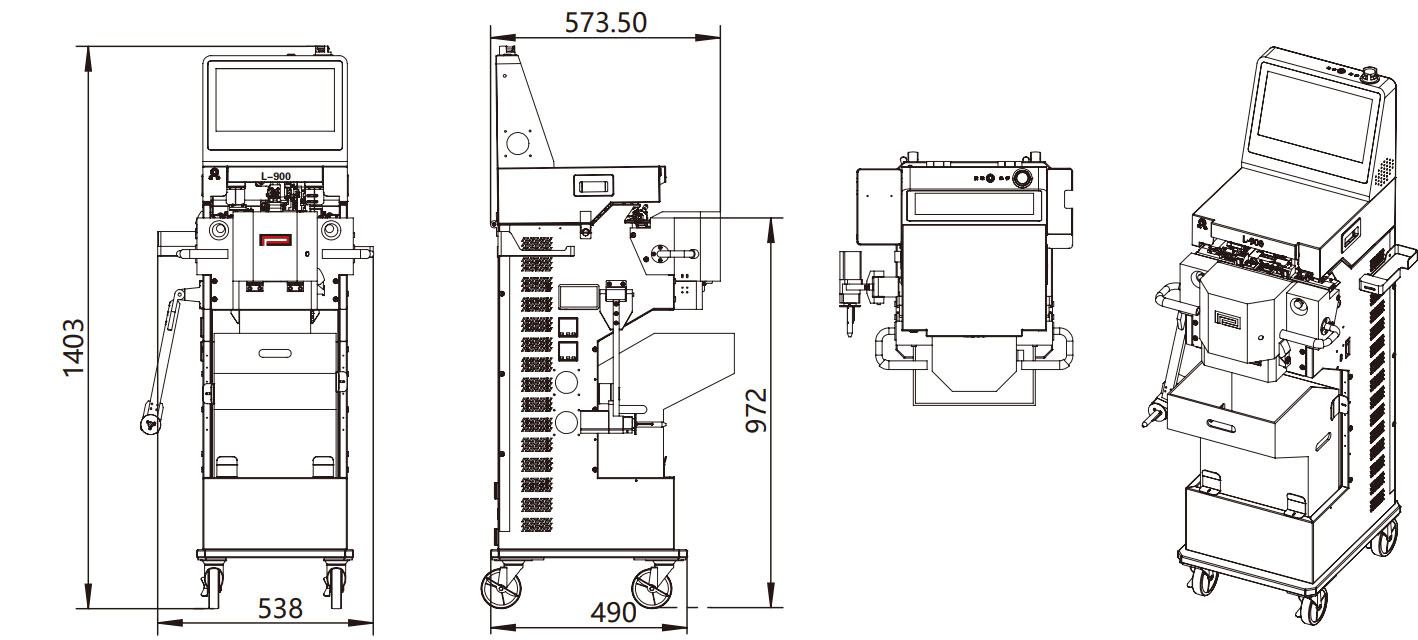

Machine Dimension (mm) |

538(W) × 573.5(D) × 1403(H) |

|

Weight (kg) |

80 |

|

|

Safety |

Fully enclosed design with safety interlock switches |

|

|

Conveyor |

Component Height (mm) |

972 |

|

Power Supply |

Power Source |

60Ah Battery |

|

Operation Time (when fully charged) |

12-16h |

|

|

Charging Voltage |

24V DC |

|

|

Power |

240W |

|

|

Motion System |

Repeatability (mm) |

0.1 |

|

Positioning accuracy of splicing tape (mm) |

±0.2 |

|

|

Carrier Tape |

Width(mm) |

8/12/16/24 |

|

Pitch (mm) |

2/4/8/12/16/20 |

|

|

Minimum Length for Splicing(mm) |

170 |

|

|

Component Reel |

Motorized Winder |

Standard Configuration |

|

Reel Size (mm) |

≤φ380 (consult Youngpool for special requirements) |

|

|

Splicing Rate |

Cycle Time (sec) |

≤10S (not including loading time) |

|

Software and Programming |

Control |

Computer Control |

|

Operating System |

Windows Interface |

|

|

Communication with MES |

Customizable |

|

|

Available Information |

Barcode Information, Battery Level, Alarms, Parameter Settings, Splicing Records |

|

|

Options and Accessories |

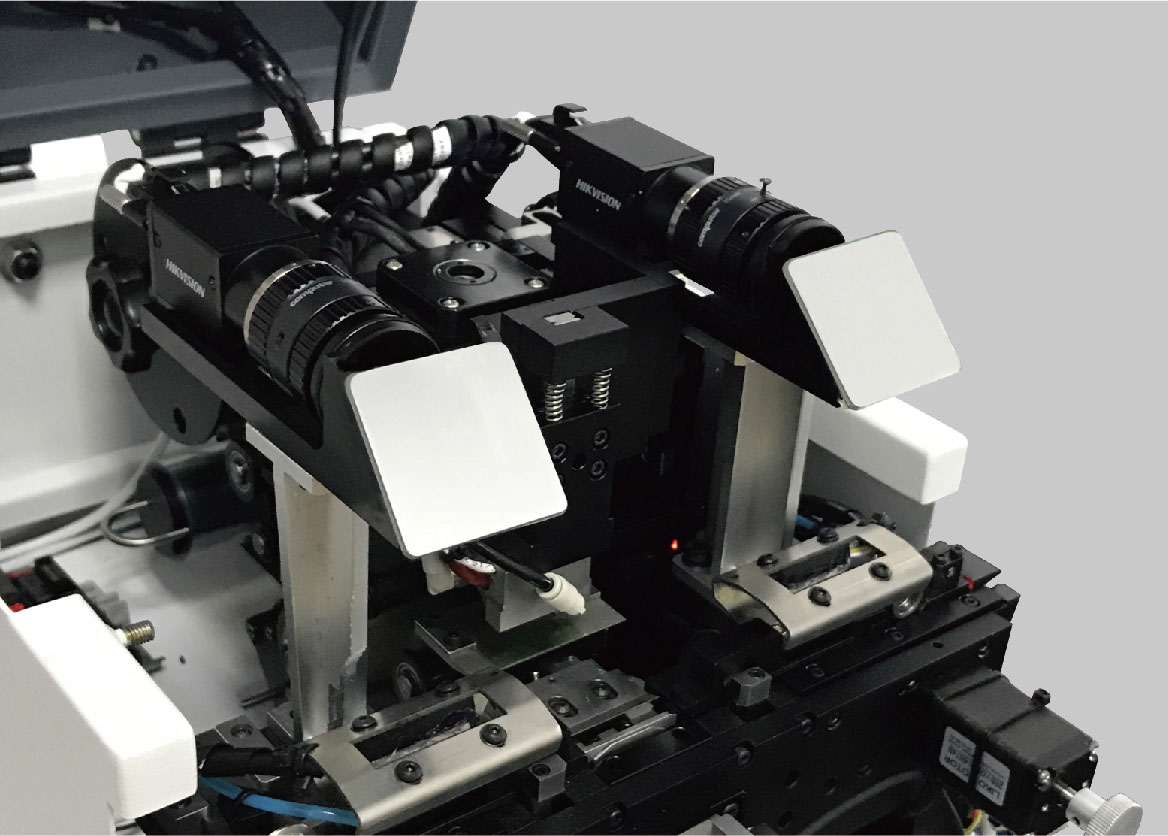

Carrier Tape Vision Inspection System |

Available as Option |

|

Power-assisted Wheels |

Available as Option |

|

|

AGV version |

Available as Option(please consult your sales agent) |

|

|

Label Printer |

Available as Option |

|

|

Barcode Scanner |

Standard Configuration |

|

|

Extension Port |

USB2.0 |

Standard Configuration |

Illustrations of Automatic Splicing System

[Adhesion strength and durability]

[Carrier Tape Vision Inspection System]

[Empty-pocket detection]

[Connecting effect display]

Splicing Machine Dimensions

● Published in July 2021 , All Rights Reserved

● All specifications are subject to change as a result of technical developments or advances. For questions on our products, please contact Youngpool Technonlogy (information@youngpool.com) or our local representative(s)

X

X