♦Stable performance and fast response

♦Advanced heat dissipation design process

♦Applicable to various automation equipment

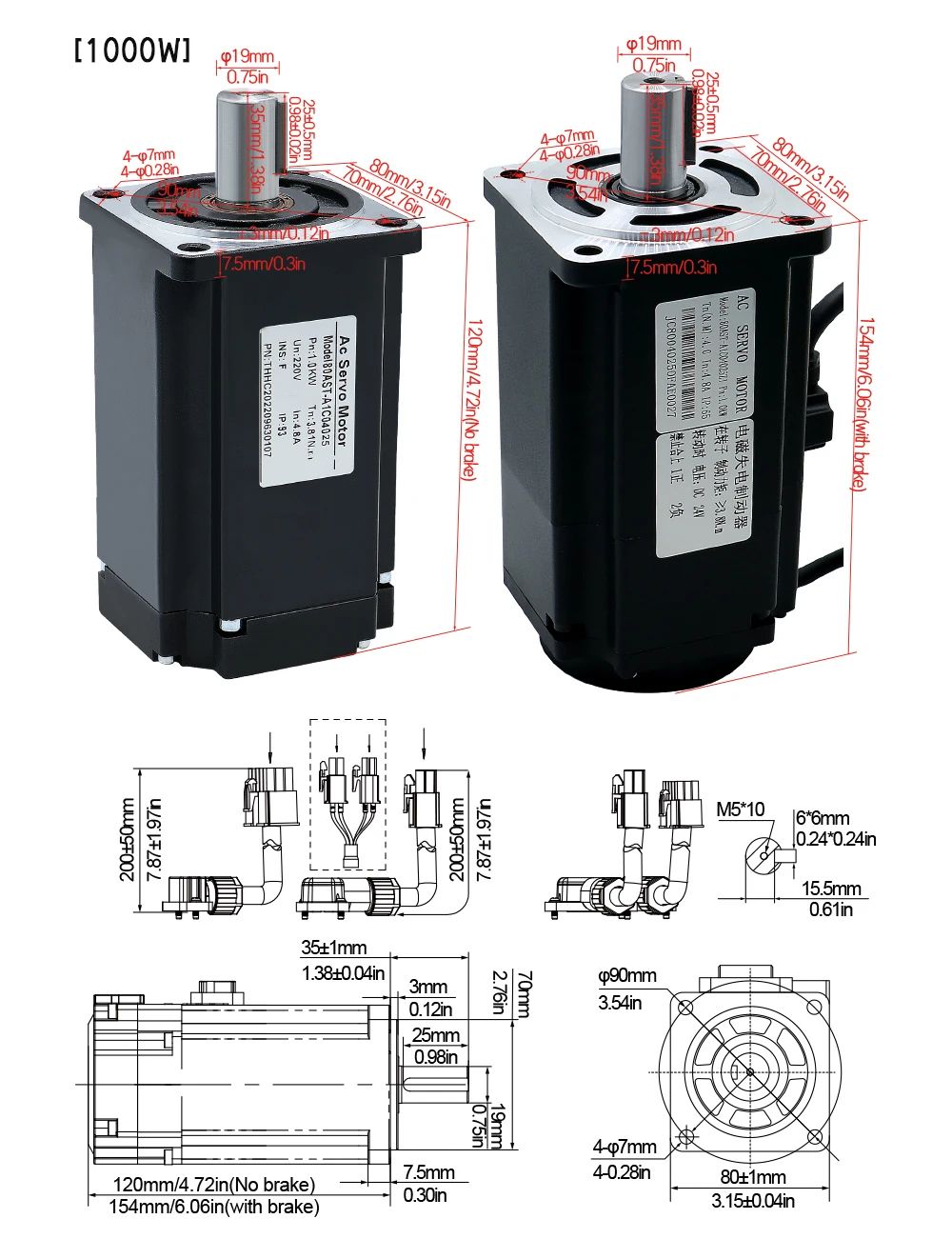

80 servo motor set

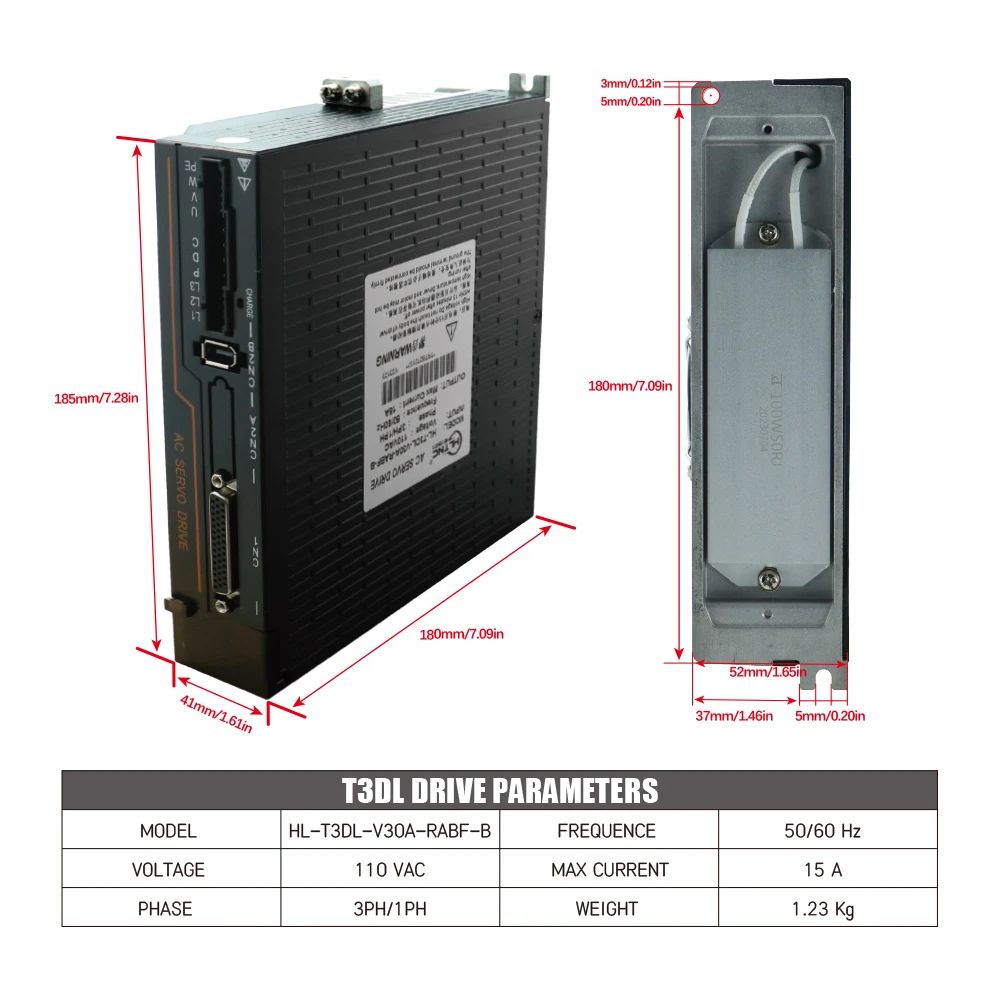

110 220V Servo Motor Kit With Magnetic 17bit Absolute Encoder + T3D 15A Driver For CNC Engraver

Technical Specification

| Servo Motor With Magnetic 17bit Absolute Encoder | ||||||

| Servo Motor Model | Motor Flange | RS485 (Modbus) |

Customized cable length |

Brake | Motor Shaft Diameter |

|

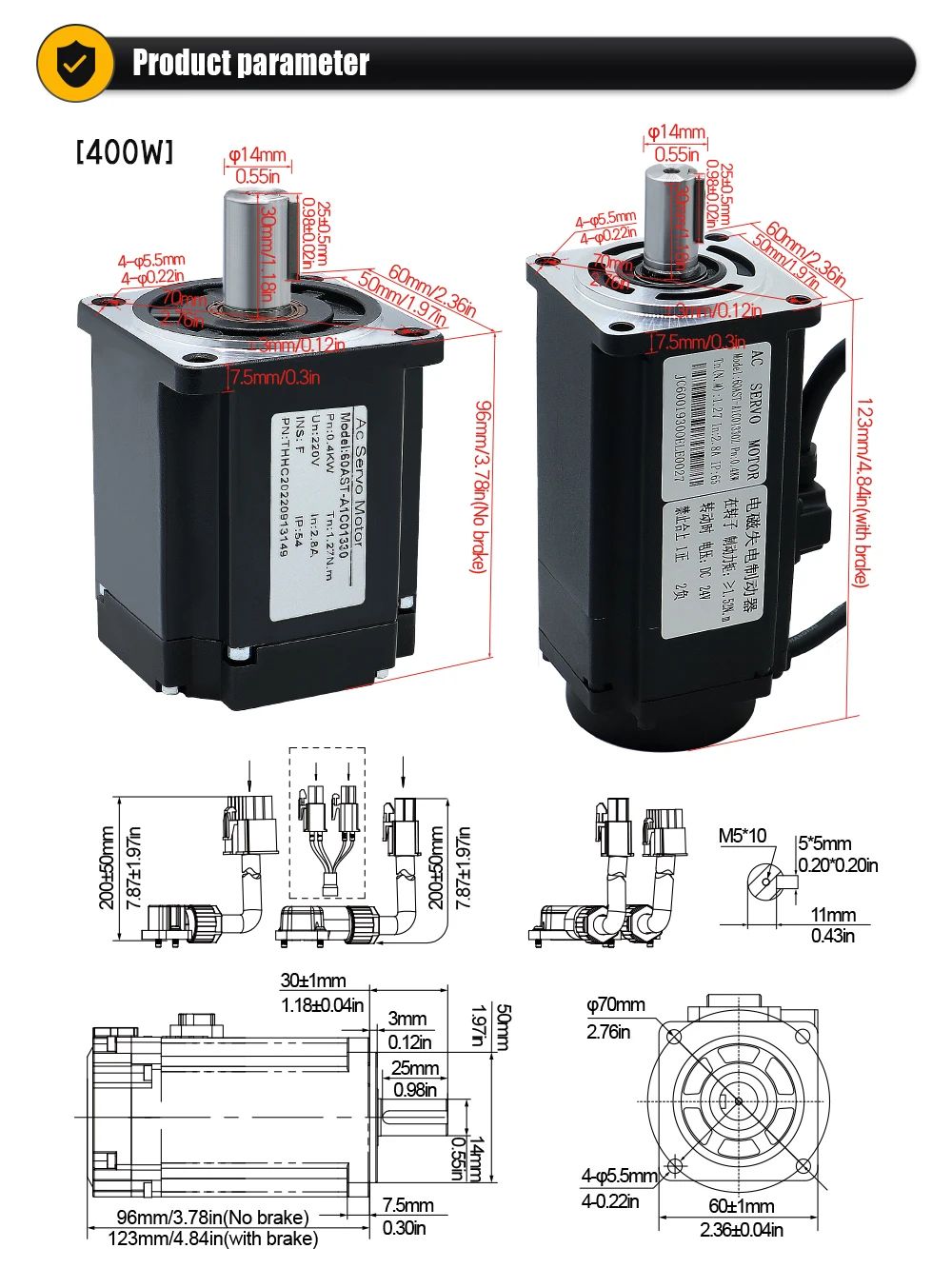

| 60AST-A1C01330 | Nema2460mmx60mm (mounting hole distance 49.5mm) |

400w | Support | Support(3-15meter) | Optional | 14mm With 5mm Key |

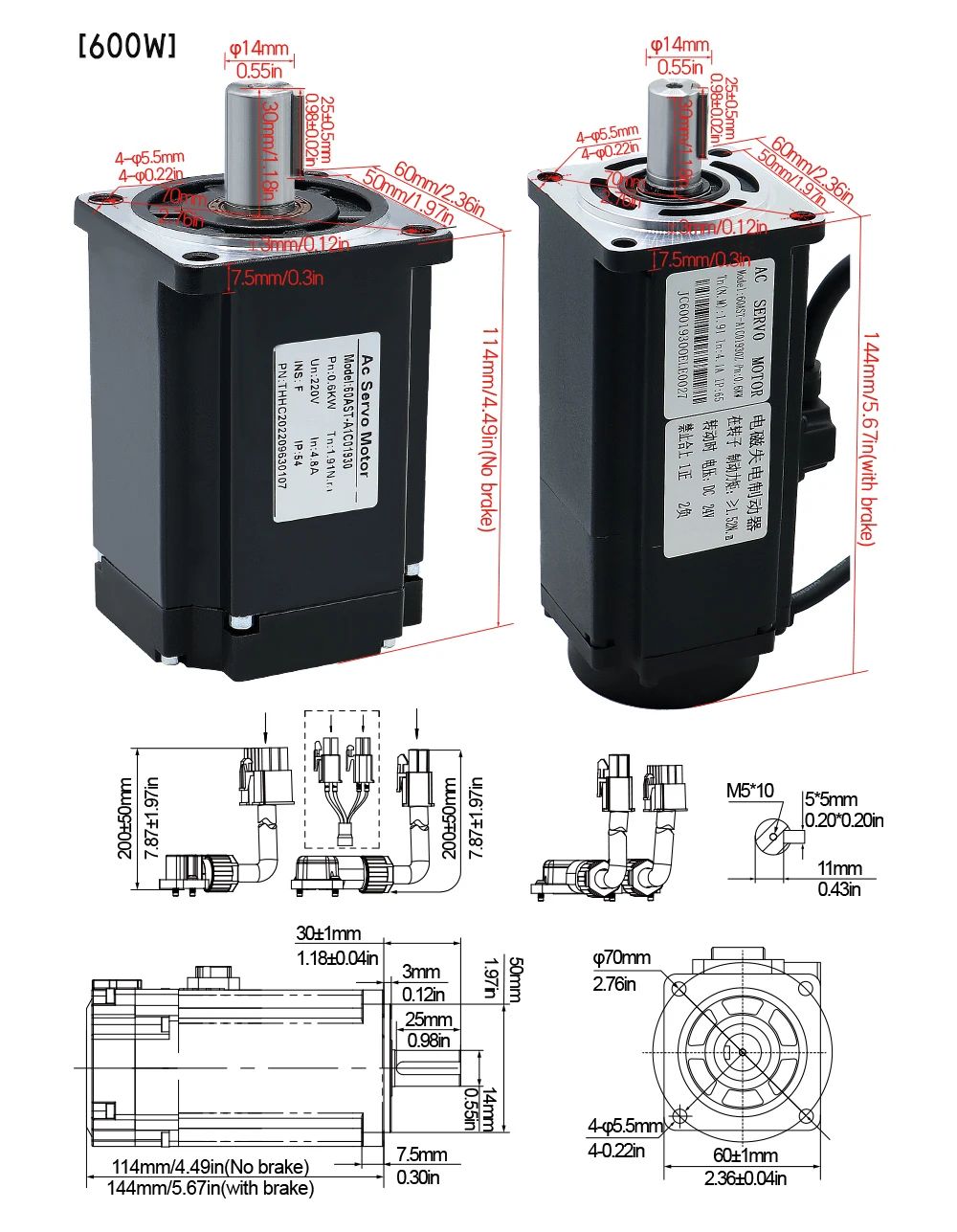

| 60AST-A1C01930 | 600w | |||||

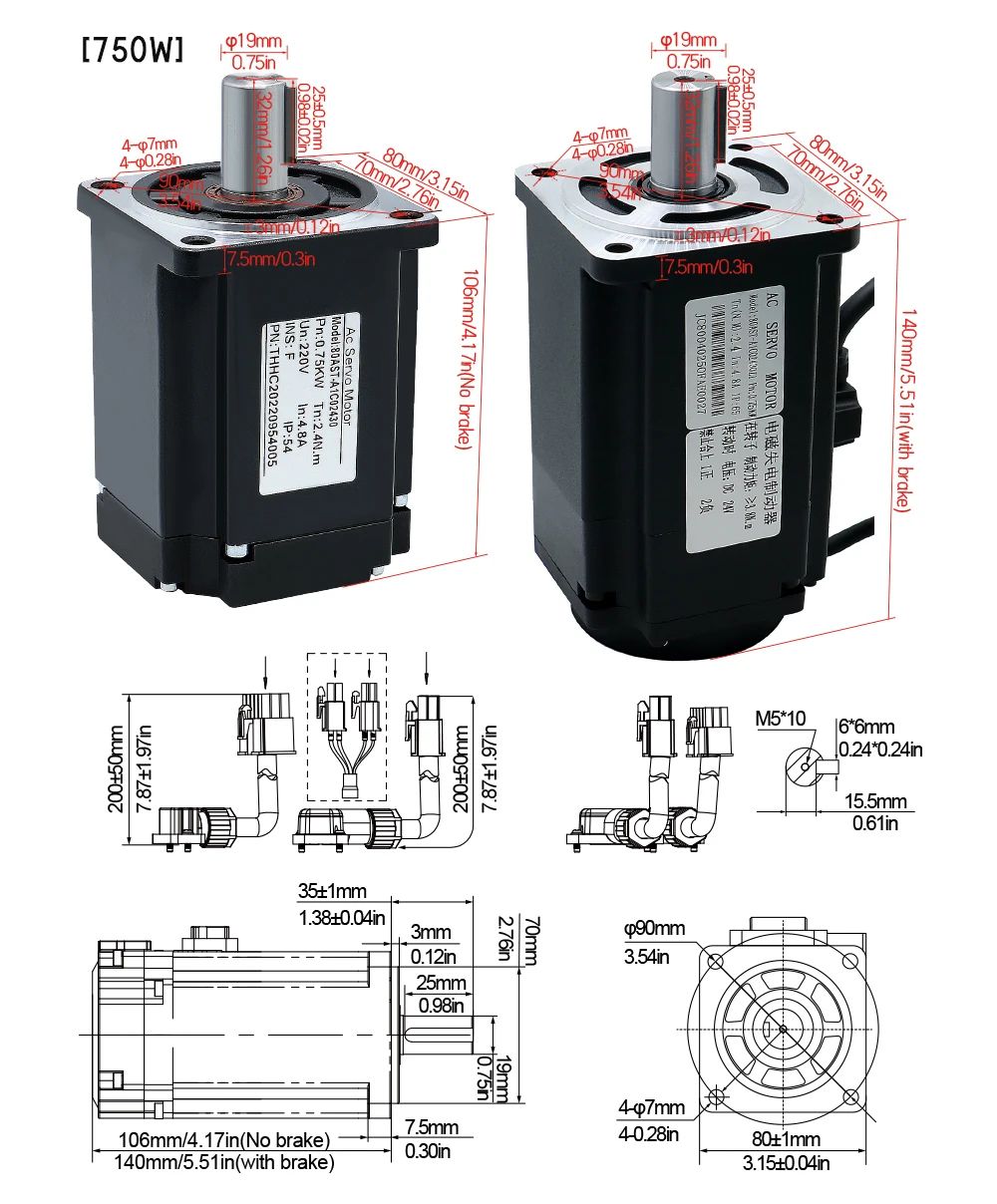

| 80AST-A1C02430 | Nema3280mmx80mm (mounting hole distance 63.6mm) |

750w | 19mm With 6mm Key |

|||

| 80AST-A1C04025 | 1000w | |||||

| Technical Specifications | ||||

| Rated Voltage ( V) | 220 | 220 | 220 | 220 |

| Rated Power ( W) | 400 | 600 | 750 | 1000 |

| Rotor pole pairs ( P ) | 5 | 5 | 5 | 5 |

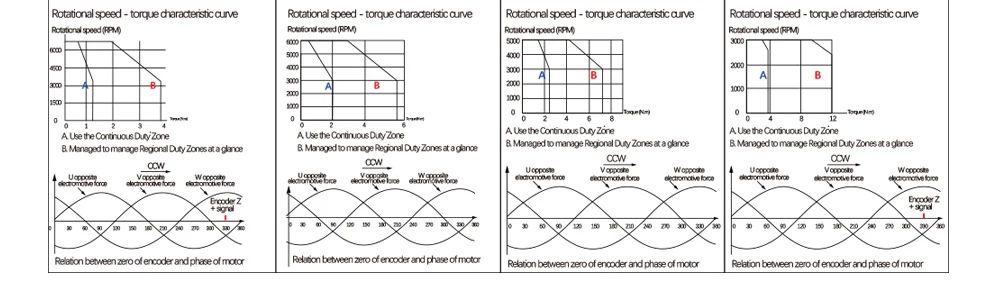

| Rated Torque ( Nm ) | 1.27 | 1.91 | 2.4 | 3.8 |

| Instantaneous max torque (Nm ) | 3.82 | 5.73 | 7.2 | 11.4 |

| Rated Speed / Max Speed (rpm) | 3000/6000 | 3000/6000 | 3000/5000 | 2500/3000 |

| Rated Current ( A ) | 2.8±10% | 4±10% | 4.8±10% | |

| Instantaneous Max Current (A ) | 8.4±10% | 12±10% | 14.4±10% | |

| Moment Coefficient (Nm/A ) | 0.42±10% | 0.54±10% | 0.5±10% | 0.93±10% |

| Back EMF Coefficient ( X10 V/rpm) | 27.5±10% | 32.5±% | 33.2±10% | 56±10% |

| Resistance (Ω ) | 3±10% ( 20℃ ) | 3.2± 10%(20 ℃) | 1.6 ± 10%(20 ℃) | 3±10%(20℃) |

| Inductance ( mH) | 7.8±20% ( 20℃ ) | 8.4±20% ( 20℃) | 9.5±20% (20℃) | 19±20% (20℃) |

| Moment of inertia ( X10V/rpm ) | 0.68 [0.73] ± 10% | 0.82[1.7] ± 10% | 1.72 [1.77]± 10% | 2.4[2.45]±10% |

| Max radial load ( N ) | 245 | 392 | ||

| Max axial load ( N ) | 74 | 147 | ||

| Weight ( KG) | 1.22 [1.65]± 10% | 1.4[1.7]±10% | 2.2[3]±10% | 2.71[3.36]±10% |

| Encoder Resolution | 10000ppr | |||

| Protection Structure | IP65 | |||

| Insulation class | F | |||

| Insulation Resistance | More than 20m Ω DC500V | |||

| Insulation Withstand voltage | AC 1500V 1minutes | |||

| Vibration Level | Rated A for operation | |||

| Turn Around | Forward turn command,viewed from load sid, counterclockwise (CCW) | |||

| Surroundings | Temperature -20℃ ~ 40 ℃, humidity 20% ~ 80% RH ( no condensation ) , altitude below 1000 | |||

| Temperature - 20℃ ~ 60℃, (no freezing) humidity 20% ~ 80% RH (no condensation) | ||||

| Impact Strength | 98m/S ² | |||

| Vibration Resistance | 49m/S ² | |||

| Power | 400w | 600w | 750w | 1000w |

| Rated Voltage DC (V) | 24±10% | |||

| Rated Power (W) | 0.3 | 0.56 | ||

| Insulation Class | F | |||

| Static Torque (Nm) | ≥1.5 | ≥2 | ≥4 | |

| Insulation Resistance (MΩ ) | >500 | |||

| Resistant to high voltage | 1500V/1S/5mA | |||

| Rotary Clearance | ≤0.5 | |||

| Operating Ambient Temperature | -10~+40 | |||

| Attract Time | ≤50 | ≤60 | ||

| Release Time | ≤20 | |||

| Attract Voltage | ≤19.2 | |||

| The release of the voltage | >1.5 | |||

| Running noise | <60 | |||

Product Display

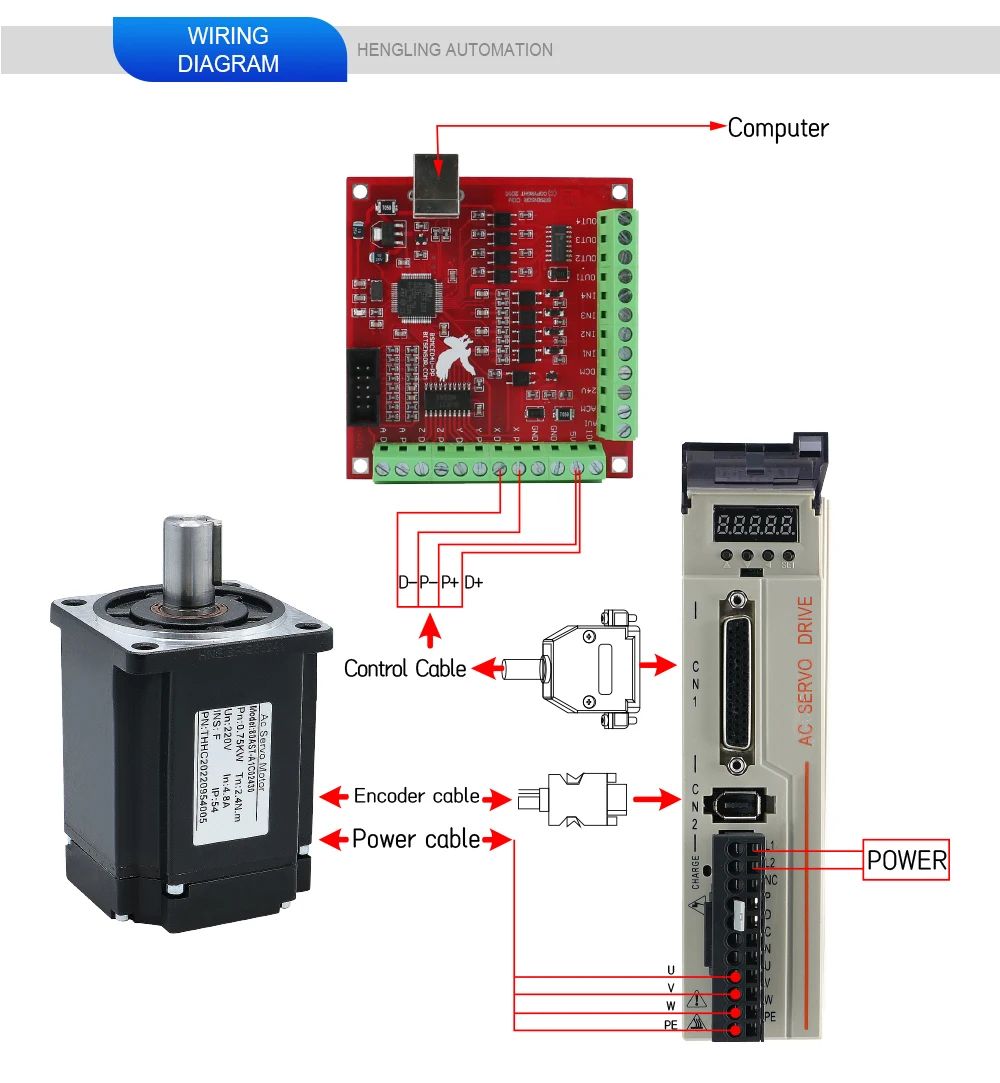

♦1* 400W 60AST-A1C01330 Servo Motor ( 17 bit absolute )/1* 600W 60AST-A1C01930 Servo Motor

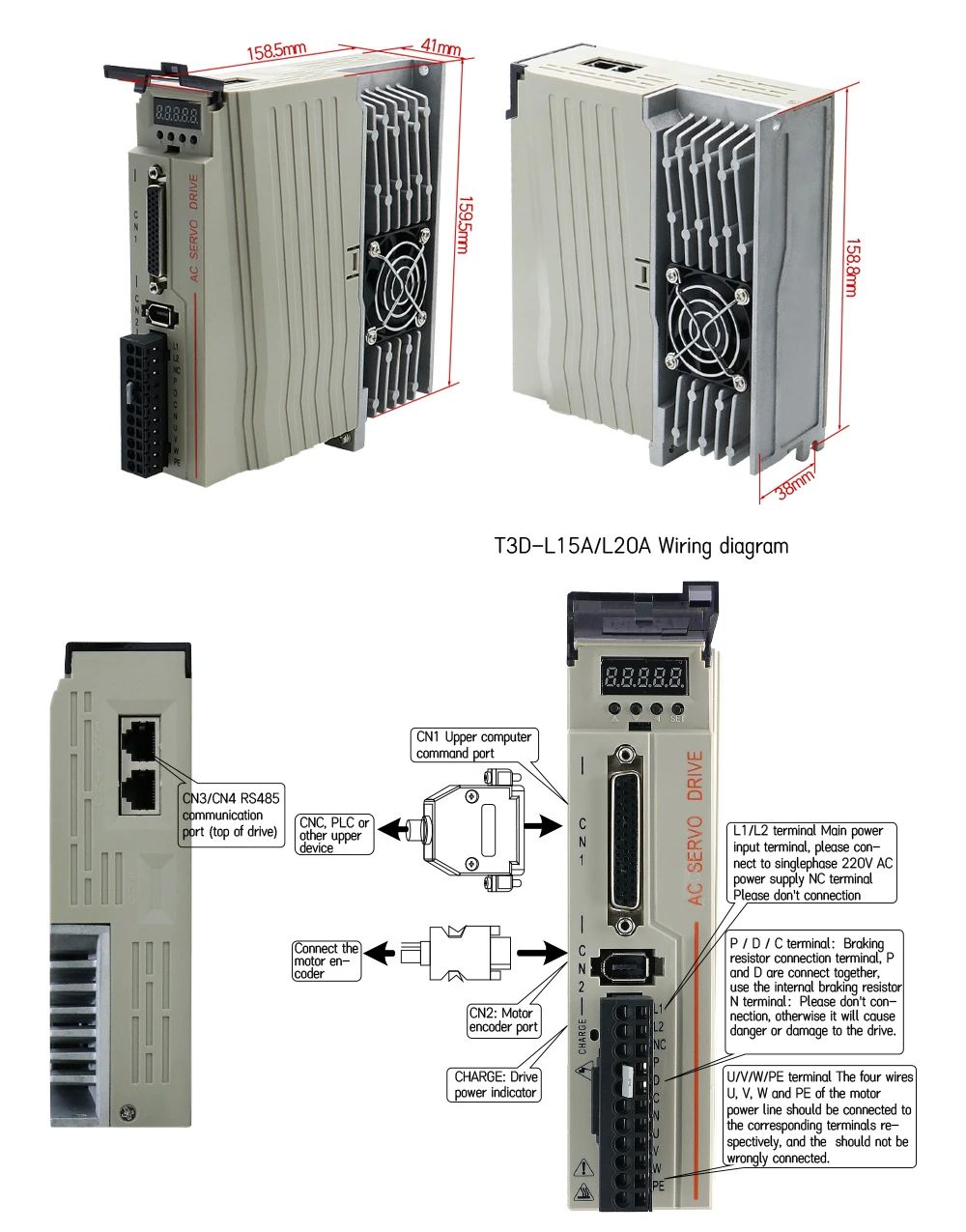

♦1* T3D-L15A AC Driver (no fans)

♦1* 3Meter Encoder Cable + Power Cable

♦1* Control Signal Cable

♦2* 2K 1/4W resistance

♦1*RS485 Cable

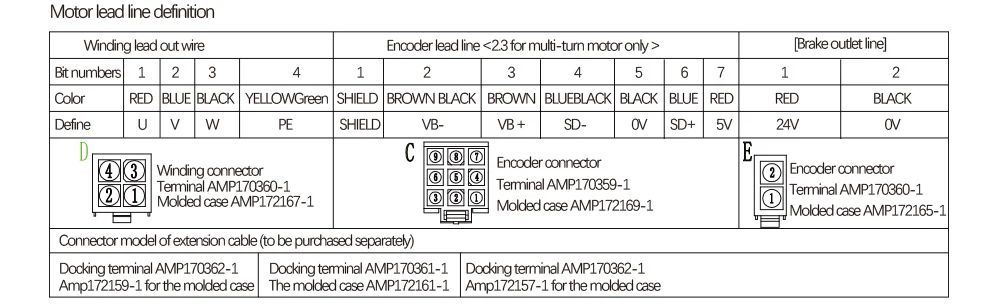

| Symbol | Name | Function |

| POW | Power Light | The decimal point of the second digital bube from the left lights up to indicate that the servo is under voltage |

| (none) | ||

| RUN | Runing light | The decinal point of the first digital tube from the left lights up to indicate that the servo is enabled |

| (none) | ||

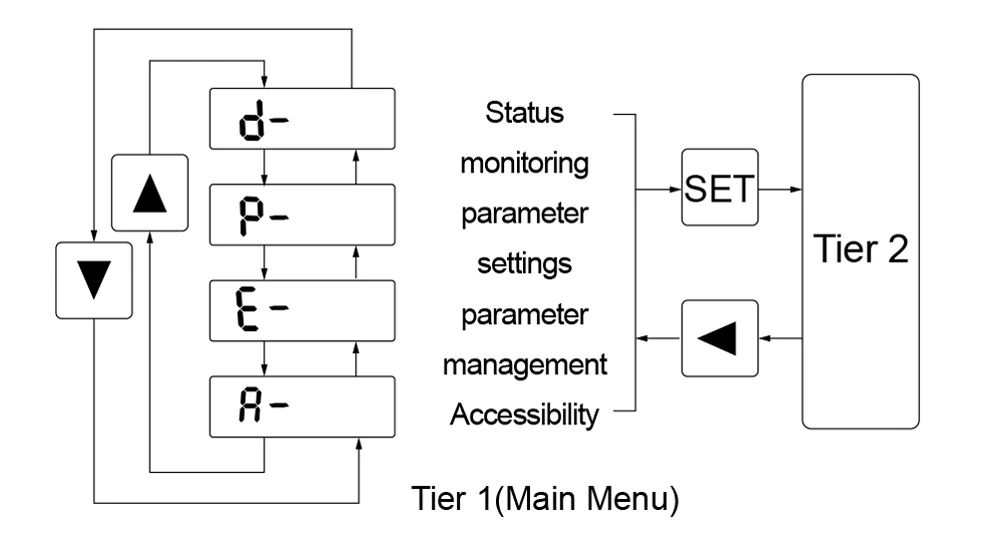

| ▲ | Add key | Increase the serial number of value, long press has repeat effect |

| ▼ | Decrease Key | Decrease the serial number of value,long preass haas repeat effect |

| ◀ | Exit Key | Menu exit, operation cancelled, |

| SET | Enter | Menu Entry,parameter modification confirmation or operation confirmation |

Common parameters:

P-036 is changed to 1 (reverse direction) 0 (positive direction) motor direction conversion parameter. The default is 1 reverse direction

P-029 (electronic gear ratio numerator) is 1 by default, the higher the value, the faster the speed

(The above parameters are general setting parameters. If you need to modify other parameters, please refer to the manual or contact the technical/sales personnel)

The following parameters are rigid adjustment parameters. No adjustment is needed if the equipment is OK

P-005 (Speed ring rigidity)

P-009 (Position ring rigidity)

P-006 (generally, the maximum setting is about 100)

P-019 (generally, the maximum setting is about 300)

The specific adjustment of rigid parameters depends on the transmission structure and load of the equipment. Contact the after-sales service personnel for specific questions.

FAQ

Can you produce according to the samples or drawings?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

What is the lead time?

For standard models, lead time is about 3~5 days after order confirmed and payment received.

For OEM orders, the delivery is about 2~3 weeks after data confirmed and payment received.

How to solve the quality problems after sales?

Take photos or videos of the problems and send to us.

We will make a satisfied solution for you within 24 hours after we confirm the problems.

X

X