-Carbon Rims

-Aluminum Braking Surface

-23/25mm Wide

-Carbon Fiber Rims vs Aluminum Brake Surface Rims

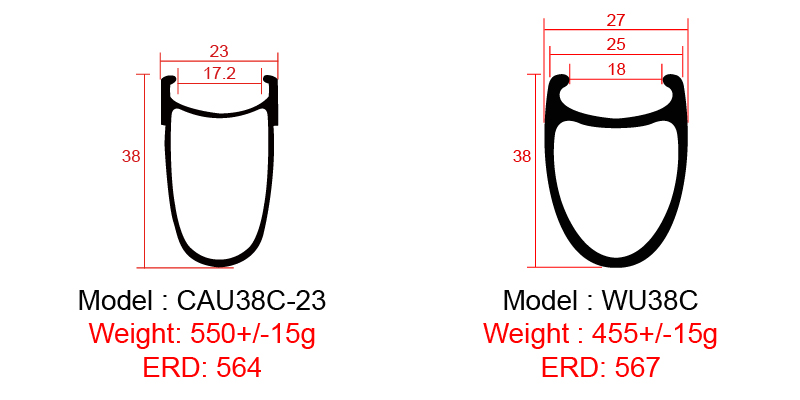

Carbon Clincher aluminum Brake Surface Details,as below:

|

Model |

CAU38C-23 | WU38C |

|

Material |

Toray T700 + Aluminum |

Toray T700 |

|

Rim Width |

23/17mm | 25/18mm |

|

Rim Depth |

38mm | 38mm |

|

Weave |

UD/3K | UD/3K/12K/Twill |

|

Finish |

Matte/Glossy | Matte/Glossy |

|

Rim Type |

Clincher | Clincher |

|

Use |

Road Bike | Road Bike |

|

Brake System |

Rim Brake | Rim Brake / Disc Brake |

|

ERD |

567 | 567 |

|

Spoke Holes |

20/24/28H | 20/24/28H |

|

Rim Weight |

550+/-15g | 455+/-15g |

|

Angle |

+/-5° | +/-5° |

|

Max Spokes Tension |

130kgf | 130kgf |

|

Max Tyre Pressure |

80 Psi | 120 Psi |

|

Max Rider Weight |

130 Kg | 120 Kg |

|

Tyre Size |

23-28C | 25-38C |

|

Decals |

Customized | Customized |

|

Warranty |

2 Years | 2 Years |

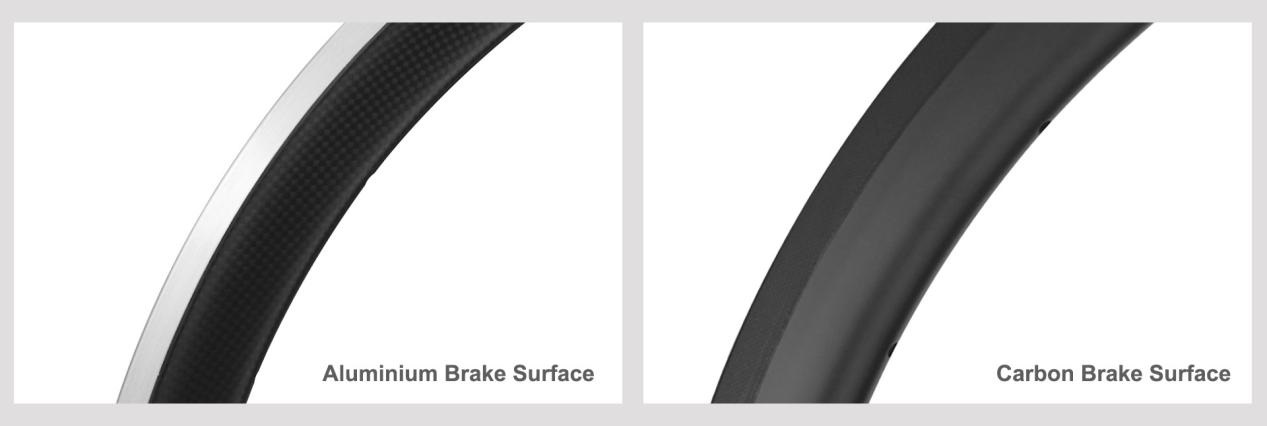

The following is the questions we met in daily inquiry,why we choose full carbon rims?Why don't we keep the aluminum wheels or aluminum brake surface carbon rims?Besides,somebody usually queried whether carbon rims brake surface durable or not.Do you have the same questions when you want to upgrade your wheelset?I think yes.In fact,Superroad still keep short run production for aluminum braking surface carbon rims.Both 23mm and 25mm wide,38/50/60/80mm available now.Take this opportunity,the difference between full carbon fiber rims and Carbon Clincher aluminum Brake Surface rims.

First of all, let's discuss the question that all riders are concerned about, is the carbon brake surface not as strong as the aluminum brake surface? Many people think that carbon brake surfaces melt when going downhill due to frictional heat. This is a wrong theory!

Nowadays, carbon rims are stronger than aluminum rims and can withstand more impact. When it comes to the problem of heat generation, the original carbon brake surface will generate heat. When using the carbon brake surface for a long time, it will generate a certain amount of heat. Now we use HTG resin. So we don't have to worry about the carbon rim brake surface will deform . We have brake pads that match the carbon brake surface. The combination of the two can achieve better results. All Superroad rims are tested before leaving the factory, make sure the wheels you buy the circles are all up to standard.

One of the best things about carbon brake surfaces is their weight. A carbon brake surface can be as strong as an aluminum brake surface, and much lighter. I believe that in the case of the same performance, you will definitely choose a lighter rim,also our suggestion. The same carbon wheel uses carbon brake surface and aluminum brake surface, the weight difference is about 100g/piece.If you build carbon wheels with aluminum braking surface,the complete weight would be more heavier.And the appearance of full carbon is all black, which is more beautiful and more in line with people's aesthetics.

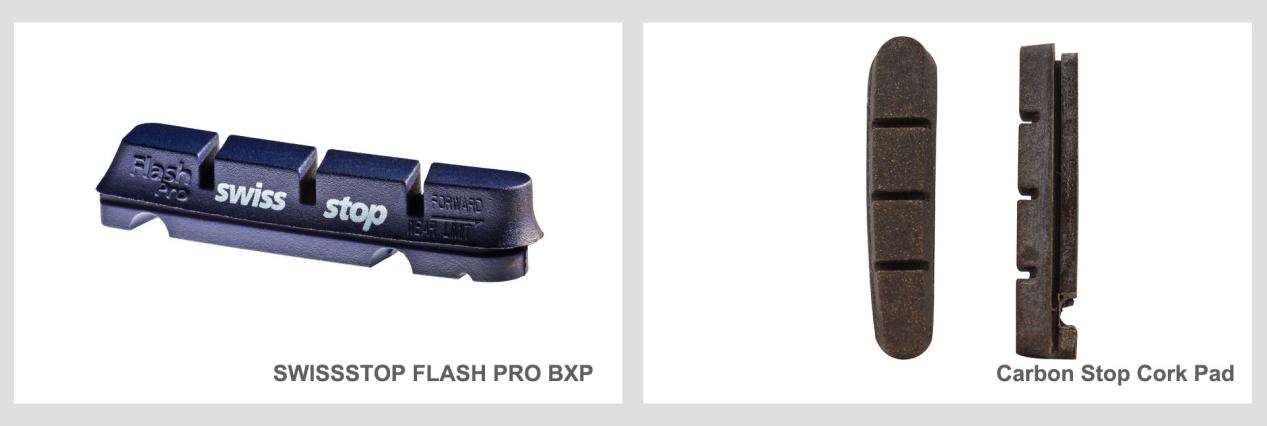

Next, let's talk about the aluminum brake surface. Initially, our rims are made of aluminum. The biggest advantage of the aluminum brake surface is that there will be no burning edge phenomenon. Carbon rim is matched with aluminum brake surface, which is more in line with the air. Dynamic design, and the weight will be much lighter than all aluminum. We specially customized a brake pad for the aluminum brake surface, and the braking effect will be better when the two are combined.We suggest SWISSSTOP FLASH PRO BXP for our carbon clincher aluminum brake surface rims,and Superroad BP01 for all carbon fiber rims use. as below:

Aluminum Wheels Pro Brake Pad Superroad BP01 Carbon Wheels Pro Brake Pad

Finally,about the PSI,difference between carbon fiber rims and carbon rims,the full carbon fiber is 130 PSI VS aluminum brake surface rims 70-80 PSI.

If you are still considering between carbon brake surface and aluminum brake surface, please feel free to contact our e-mail, we will provide you with the best service.

X

X