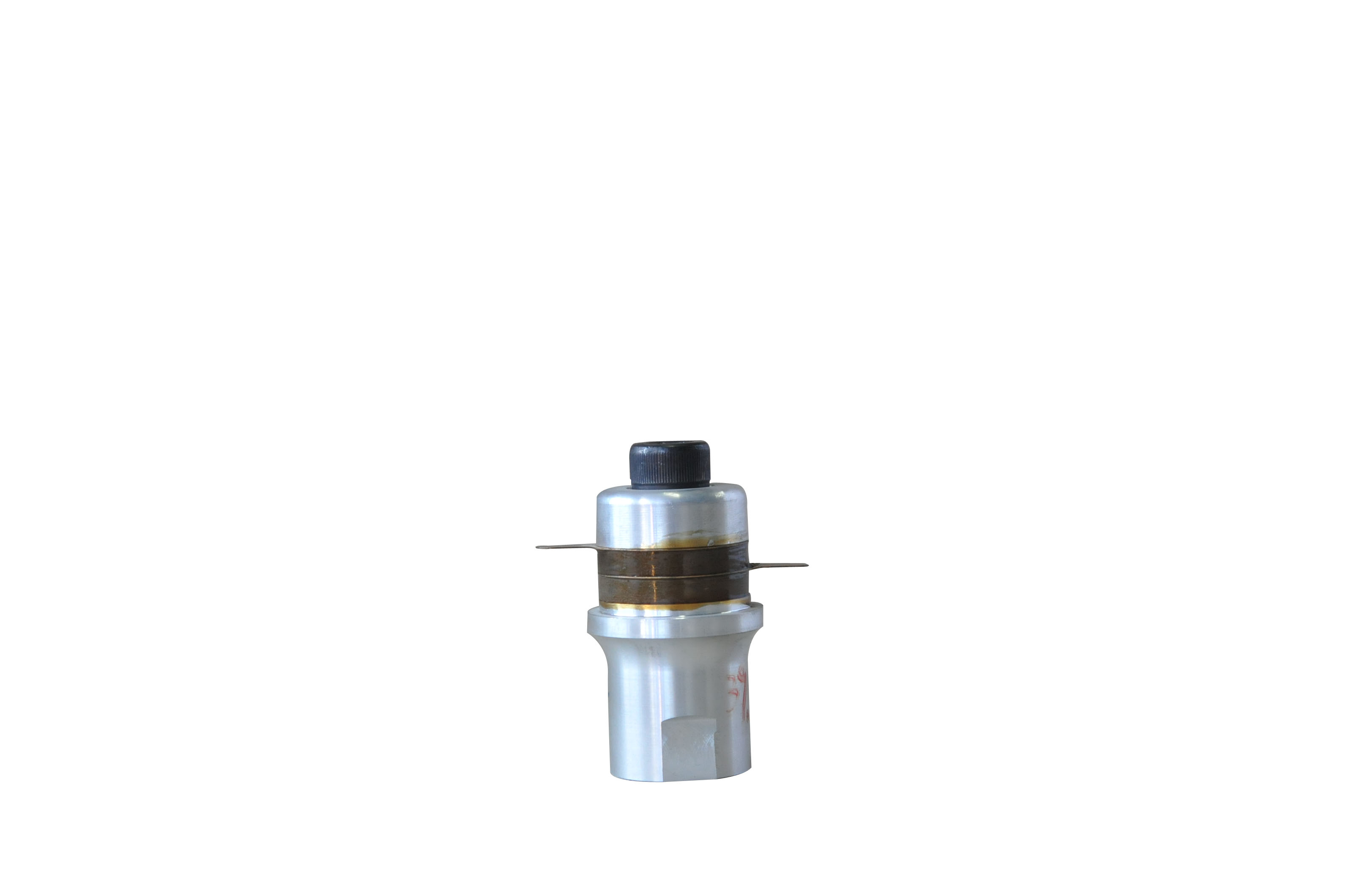

3040-2D High Frequency Ultrasonic Transducer For Cutting

3040-2D High Frequency Ultrasonic Transducer For Cutting

|

Minimum Order Quantity: |

10 Set |

|

Price: |

|

|

Packaging Details: |

Foam case |

|

Delivery Time: |

In 7 Working Days |

|

Payment Terms: |

T/T, WESTERN UNION |

|

Supply Ability: |

5000 Sets/Month |

Quick Detail:

Stabilized power and high reliability widely application

Application:

Transducer, in electronics, a device that converts electric energy into some other form of energy, especially the application of mechanical energy in industry is more and more significant.

We mainly supply two kinds of Ultrasonic transducers: NTK type and Branson type. Widely used in ultrasonic welding, ultrasonic cutting,ultrasonic sewing machine,ultrasonic sonochemistry, ultrasonic wire stripping machine,ultrasonic nebulizer,Ultrasonic riveting machine.

Description:

1.High Efficiency: of high mechanical factor. High transfer efficiency is obtained when working in resonance frequency.

2.Big amplitude: designed and chosen by computer, high oscillation speed and big amplitude in front operculum.

3.Big Power: under the function of the prestressed force screw rod, the piezoelectricity ceramics can work freely in the highest level of power.

4.In good heat resistance: of small resonance impedance, less heat produced, can be used in a wide range of temperature with long life and high reliability.

Specifications:

|

The columnar type NTK TYPE (stabilized power and high reliablity widely application) |

|||||||||||

|

Item No. |

Connect screw (Size) |

Ceramic diameter (mm) |

Quantity of Ceramic (pc) |

Resonance frequency (khz) |

Resistance (Ω) |

Capacitance |

Input power (W) |

Max. Amplitude (um) |

|||

|

|

|

|

|

|

|

Yellow |

Grey |

Black |

|

|

|

|

7015-4Z |

M20 X 1.5 |

70 |

4 |

15 |

15 |

12500-14000 |

/ |

17000-19000 |

2600 |

10 |

|

|

6015-4Z |

M20 X 1.5 or M16 X 1 |

60 |

4 |

15 |

15 |

8000-10000 |

10000-12000 |

12500-13500 |

2200 |

10 |

|

|

6015-6Z |

M20 X 1.5 |

60 |

6 |

15 |

15 |

14000-16000 |

/ |

19500-21000 |

2600 |

10 |

|

|

5015-4Z |

M18 X 1.5 |

50 |

4 |

15 |

15 |

12000-13000 |

13000-14300 |

15000-17000 |

1500 |

8 |

|

|

4015-4Z |

M16 X 1 |

40 |

4 |

15 |

15 |

10000-11000 |

10500-11500 |

|

700 |

8 |

|

|

5520-4Z |

M18 X 1 |

55 |

4 |

20 |

15 |

10000-11000 |

10500-11500 |

14300-20000 |

2000 |

8 |

|

|

5020-6Z |

M18 X 1.5 |

50 |

6 |

20 |

15 |

18500-20000 |

/ |

22500-25000 |

2000 |

8 |

|

|

5020-4Z |

M18 X 1.5 |

50 |

4 |

20 |

15 |

11000-13000 |

13000-15000 |

15000-17000 |

1500 |

8 |

|

|

5020-2Z |

M18 X 1.5 |

50 |

2 |

20 |

20 |

6000-6500 |

6500-7000 |

8000-9000 |

800 |

6 |

|

|

4020-4Z |

1/2-20UNF |

40 |

4 |

20 |

15 |

9000-10000 |

9500-11000 |

/ |

900 |

6 |

|

|

4020-2Z |

1/2-20UNF |

40 |

2 |

20 |

25 |

/ |

4800-5500 |

/ |

500 |

5 |

|

|

5025-2Z |

M12 X 1 |

50 |

2 |

25 |

25 |

5000-5600 |

/ |

7000-8000 |

500 |

4 |

|

|

3828-2Z |

1/2-20UNF |

38 |

2 |

28 |

30 |

3800-4300 |

/ |

/ |

500 |

3 |

|

|

3828-4Z |

1/2-20UNF |

38 |

4 |

28 |

30 |

7600-8500 |

/ |

10500-12000 |

800 |

4 |

|

|

3028-2Z |

3/8-24UNF |

30 |

2 |

28 |

30 |

2700-3100 |

3400-3800 |

/ |

400 |

3 |

|

|

2528-4Z |

M8 X 1 |

25 |

4 |

28 |

30 |

3900-4300 |

/ |

/ |

400 |

4 |

|

|

2528-2Z |

M8 X 1 or 3/8-24UNF |

25 |

2 |

28 |

35 |

1950-2200 |

2200-2500 |

/ |

300 |

3 |

|

|

3030-4Z |

M10 |

30 |

4 |

30 |

30 |

/ |

6200-6900 |

/ |

700 |

4 |

|

|

3035-2Z |

3/8-24UNF |

30 |

2 |

35 |

40 |

2700-3100 |

/ |

/ |

500 |

2 |

|

|

3035-4Z |

M10 X 1 |

30 |

4 |

35 |

30 |

5000-6200 |

/ |

/ |

800 |

3 |

|

|

2535-2Z |

M8 X 1 |

25 |

2 |

35 |

40 |

1900-2200 |

/ |

/ |

400 |

2 |

|

|

2540-2Z |

3/8-24UNF |

25 |

2 |

40 |

40 |

/ |

2000-2300 |

/ |

500 |

2 |

|

|

3040-4Z |

M10 |

30 |

4 |

40 |

30 |

5500-6200 |

/ |

/ |

1000 |

2 |

|

|

3050-4Z |

M8 |

30 |

4 |

50 |

30 |

5500-6200 |

/ |

/ |

600 |

2 |

|

|

1560-2Z |

M6 X 0.75 |

15 |

2 |

60 |

60 |

/ |

/ |

700-800 |

100 |

1 |

|

|

1070-2Z |

M4 |

10 |

2 |

70 |

200 |

/ |

/ |

350-400 |

100 |

1 |

|

|

The upside-down trumpet type BRANSON TYPE (Larger amplitude and bigger output power, high-sound intensity and high-power density application) |

|||||||||||

|

Item No. |

Connect screw (Size) |

Ceramic diameter (mm) |

Quantity of Ceramic (pc) |

Resonance frequency (khz) |

Resistance (Ω) |

Capacitance |

Input power (W) |

Max. Amplitude (um) |

|||

|

|

|

|

|

|

|

Yellow |

Grey |

Black |

|

|

|

|

7015-4D |

M20 X 1.5 |

70 |

4 |

15 |

15 |

12500-14000 |

/ |

17000-19000 |

2600 |

11 |

|

|

6015-4D |

M18 X 1.5 |

60 |

4 |

15 |

15 |

9000-10000 |

10000-11000 |

/ |

2200 |

11 |

|

|

6015-6D |

1/2-20UNF |

60 |

6 |

15 |

15 |

19000-20500 |

/ |

23000-25000 |

2600 |

11 |

|

|

5015-6D |

1/2-20UNF |

50 |

6 |

15 |

15 |

17000-19000 |

/ |

23000-25000 |

2000 |

11 |

|

|

5020- 4DS |

1/2-20UNF |

50 |

4 |

20 |

15 |

11000-12000 |

12000-13500 |

/ |

1300 |

8 |

|

|

5020-4D |

1/2-20UNF |

50 |

4 |

20 |

15 |

11000-12000 |

12000-13500 |

14500-16000 |

1500 |

8 |

|

|

5020-6D |

1/2-20UNF |

50 |

6 |

20 |

15 |

19000-21000 |

/ |

22500-25000 |

2000 |

10 |

|

|

4020-6D |

1/2-20UNF |

40 |

6 |

20 |

15 |

13500-15000 |

/ |

/ |

1500 |

10 |

|

|

4020-4D |

1/2-20UNF |

40 |

4 |

20 |

15 |

8500-9300/ 9500-10500 |

10000-11000 |

10500-11500 |

900 |

8 |

|

|

3020-6D |

3/8-24UNF |

30 |

6 |

20 |

15 |

8000-9000 |

/ |

/ |

600 |

9 |

|

|

3030-4D |

M8 or M8 X 1 |

30 |

4 |

30 |

20 |

/ |

6200-6900 |

/ |

800 |

5 |

|

|

3535-2D |

M8 X 1 |

35 |

2 |

35 |

25 |

/ |

/ |

4500-5000 |

600 |

9 |

|

|

3535-4D |

M8 X 1 |

35 |

4 |

35 |

20 |

6600-7400 |

/ |

9000-10000 |

1000 |

4 |

|

|

3035-4D |

1/2-20UNF |

30 |

4 |

35 |

20 |

5500-6200 |

/ |

9200-10200 |

800 |

4 |

|

|

2535-4D |

M8 |

25 |

4 |

35 |

25 |

3900-4300 |

/ |

/ |

500 |

4 |

|

|

3040-2D |

M8 |

30 |

2 |

40 |

30 |

/ |

3400-3800 |

/ |

500 |

2 |

|

|

2540-4D |

M8 |

25 |

4 |

40 |

30 |

4500-5300 |

/ |

/ |

500 |

3 |

|

|

2040-2D |

M8 |

20 |

2 |

40 |

40 |

1100-1300 |

1150-1350 |

/ |

300 |

2 |

|

PS:we can also customize depend on your requirements.

Competitive Advantage:

Higher power

More stable

Longer use life

Imported ceramic chip

X

X