TAITIAN offers hydraulic die spotting press that can be custom built to fit the needs of high precision die spotting. Hydraulic die spotting press also called die tryout press, mould tryout press , our die spotting presses offer excellent performance and are very reliable and can be used for efficient and quick die/mould try out.

Main Specification:

We are able to custom manufacture hydraulic die spotting press machine/die tryout presses in a wide range of sizes and capacities as per customers’requirement.

|

Part No. |

TT-LM1500T/MY |

||

|

Nominal Pressure |

Tons |

1500 |

|

|

Lifting Pressure |

Tons |

150 |

|

|

Max.Stroke of Slide |

mm |

2600 |

|

|

Max.Daylight |

mm |

2650 |

|

|

Working Table |

L-R |

mm |

3200 |

|

F-B |

mm |

2500 |

|

|

Slide Speed |

Fast Approach |

mm/s |

350 |

|

Pressing |

mm/s |

10-1 |

|

|

Fast Return |

mm/s |

200 |

|

|

Approx.Total Power |

KW |

200 |

|

|

Approx.Overal Dimension |

mm |

10855×4855×10985 |

|

Characteristics:

1. Such high precision die spotting press is specially designed for quick die/mould try out. The capacity ranges from 1000KN to 30000KN.

2. This kind die spotting press adopt special safety loop to ensure high safety and working efficiency as per the current production need of speed as well as mechanical safety.

3. Safe and reliable control system makes easy operation and high working efficiency. The press is designed and manufactured as per CE standards.

4. Systemized hydraulic circuit, with introduction of special logic loop design, is characterized by leak-prevention , anti-vibration and easy-maintenance.

5. Each press is made under strict quality control to assure the best performance and accuracy.

6. The press is equipped with moving bolster or die change trolley for easy unloading of products and fast die change.

Options:

Applications:

Taitian’s die tryout presses are primarily used for the testing and trying out of dies/moulds to ensure manufacturing precision and smooth parts manufacturing, die tryout presses are widely used in mould factories and other automobile industries.

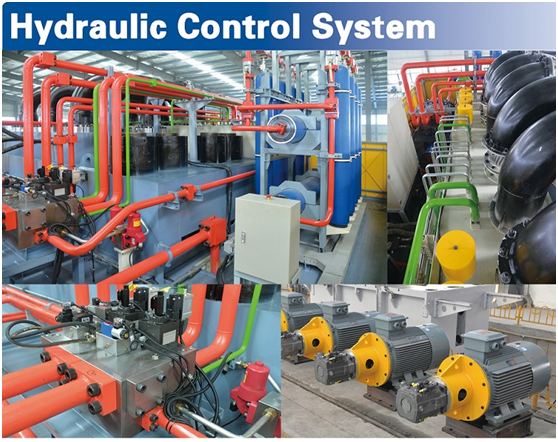

Hydraulic Control System

Hydraulic control system takes high precision logic valving system as standard. Pipeline configuration is simple and clear, making maintenance easy. Pipeline connection way preferentially adopts flange joint to avoid oil leakage.

All motors, pumps and pipes are fitted based on advanced Taiwan technology to achieve shock-resistance.

Electric Control System

Electric box is featured with dustproof, waterproof and oil proof. Adopt Schneider electric units to ensure high quality. All units to ensure high quality. All units have labels, so it's clear to identify and easy to maintain.

Production Process:

Certification:

X

X